ItemNo :

LITH-MDA-8000BMOQ :

1Color :

optionalPort :

Xiamen PortCompliance:

CEWarranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com8000A Transistor Manual Spot Welder for Nickel Plated and Pure Nickel Welding

Introduction:

Transistor welding power supply is a high-precision, high-speed and high current transistor welding power supply that performs high-speed switching through the power switch tube and performs closed-loop feedback control on the voltage and current between welding electrodes collected in real time.

Main Function:

Cylindrical battery, Prismatic battery, Polymer battery Pneumatic spot welding with nickel sheet.

Performance characteristics:

Welding power supply refers to the power supply for CO2 gas shielded welding, which adopts flat characteristics or slow drop external characteristics, and the no-load voltage is 38 ~ 70V. Strong arc self-regulation, large short-circuit current, easy arc striking and non stick wire. During operation, the arc will feel calm, soft, elastic and small splash. Welding, also known as fusion welding and fusion welding, is a manufacturing process and technology for joining metals or other thermoplastic materials such as plastics by heating, high temperature or high pressure. Welding achieves the purpose of joint through the following three ways:

1. Fusion welding - heat the workpiece to be joined to make it locally melt to form a molten pool. After the molten pool is cooled and solidified, it can be joined. If necessary, it can be supplemented by filler. It is suitable for the welding processing of various metals and alloys without pressure.

2. Pressure welding - the welding process must exert pressure on the weldment, which belongs to the processing of various metal materials and some metal materials.

3. Brazing - use the metal material with lower melting point than the base metal as the solder, use the liquid solder to wet the base metal, fill the joint gap, and diffuse with the base metal to realize the link weldment. It is suitable for welding of various materials, as well as different metals or dissimilar materials.

Specification:

|

supply voltage |

Single phase :AC100V-120V or AC200V-240V 50/60Hz |

|

Spot welding power |

MDA-8000B Transistor spot welding power |

|

Welding output power |

Max 8000A |

|

Nickel strip thickness |

0.06-0.2mm nickel plated or pure nickel strip 0.21-0.4mm nickel strip requires bump welding |

|

Working way |

Pneumatic welding |

|

Welding platform |

L600mm*W300mm |

|

Parameter setting |

Touch way |

|

Power at 0.1% duty cycle |

SQ1=9KVA |

|

Power at 50% duty cycle |

S50=0.36KVA |

|

Communication interface |

RS485, RS232 |

|

Canonical storage quantity |

16 group |

|

Cooling mode |

Forced air cooling |

|

Relative temperature |

-10-55C |

|

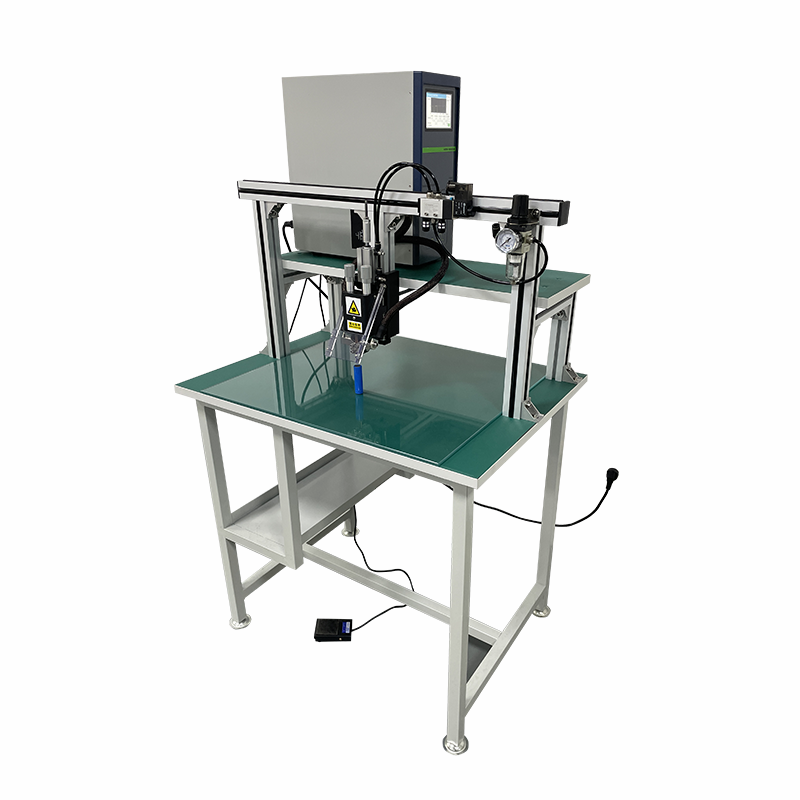

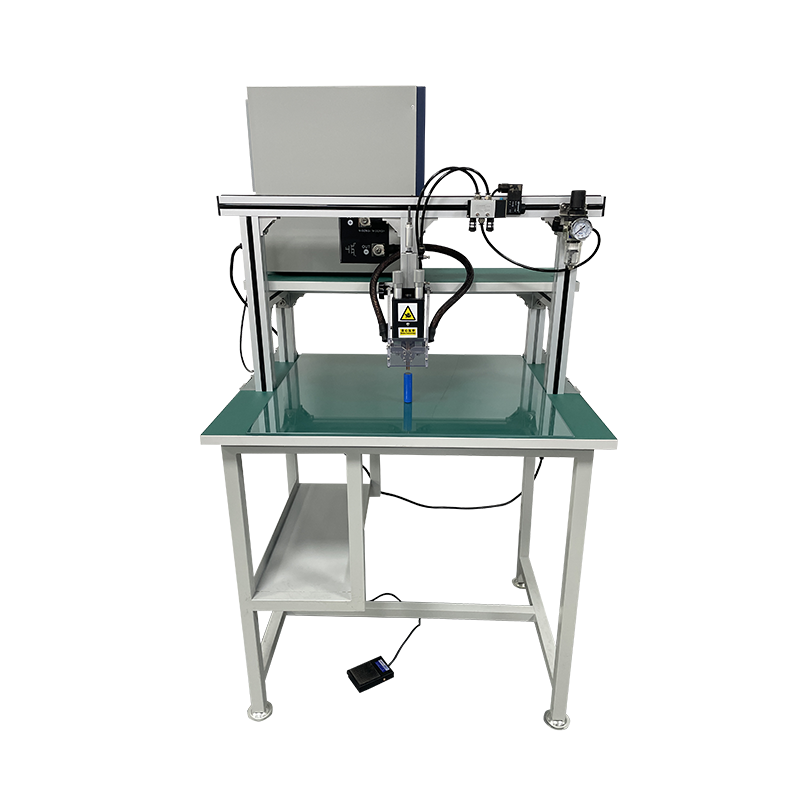

Machine Size |

L900*W900*H1350mm |

|

Welding power supply weight |

About 50kg |

Scope Range:

Spot Welding Machinie

Type

Product Name

Features

Picture

Link

Manual

Pneumatic Spot Welding Machine

Welding Thickness:0.03 -0.25mm

Air Pressure Range:0.1 - 0.7 Mpa

AC Plus Pneumatic Spot Welding Machine

Welding Thickness:0.03~0.2mm

5000A/8000A Pneumatic Inverter DC Spot Welding Machine

Maximum thickness of parallel welding:0.03mm~0.5mm

Maximum Output Short Circuit Current:5000A or 8000A

DC Output Spot Welding Machine

Maximum thickness of parallel

welding:0.03mm~0.5mm

https://www.lithmachine.com/High-Precision-DC-Output-Spot-Welding-Machine-Tab-Welder_p364.html

Automatic

Automatc Single Side Spot WeldingMachine(Pneumatic/Electric)

Welding travel:400x500mm

Welding Speed:0.35s/point; 2800pcs / hour

Automatic Single Side Rotary Welding Head Spot Welding Machine(Pneumatic/Electric)

The rotatable welding head can prevent the sticking of the needle. In addition, if it is a nickel strip with different fork directions, the rotating welding head is needed. Welding travel:400x500mm Welding Speed:0.35s/point; 2800pcs / hour

Automatic Double Sides Spot Welding Machine (Pneumatic/Electric)

Welding travel:400x500mm Spot welding speed: 0.3s/point; 5000pcs/h

https://www.lithmachine.com/Automatic-18650-26650-32650-Cylindrical-Battery-Pack-Double-Sides-Spot-Welding-Machine-for-Battery-Assembly_p369.html

![]()

Related Machine

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975