ItemNo :

LITH-Solid-StateMOQ :

1Warranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.comSolid State Battery Laboratory Pilot Assembly Line Fabrication Machines

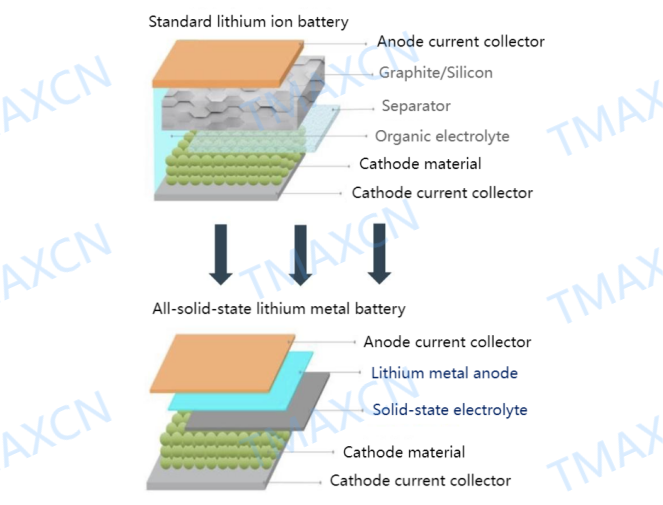

Solid state batteries are a type of battery that uses solid electrodes and solid electrolytes, offering high safety and high energy density by weight and volume. They are expected to meet the increasingly demanding and often conflicting technical requirements in the development of power batteries, making them one of the important directions for the future of power battery development.

Key Performance Attributes

|

Performance |

Reason for Improvement |

Potential Application Advantages |

|

High Safety |

Utilizes inorganic non-flammable electrolyte with good thermal stability |

Simplifies system safety protection design, reduces constraints on battery system layout |

|

High Energy Density |

Capable of adopting bipolar plate structures, compatible with high-capacity anode and cathode materials such as lithium metal |

Enhances battery module energy density, potentially doubling it, and may reduce manufacturing costs |

|

High Power Characteristics |

Ion hopping transport mechanism of solid electrolytes, with high ionic conductivity and lithium-ion transference numbers |

Improves fast charging performance, matching the needs of electric vehicles |

|

Good Temperature Adaptability |

Operates within a wide temperature range of -30~100℃, with solid electrolytes that neither freeze nor vaporize |

Simplifies cooling mechanisms, broadening application scenarios for electric vehicles |

|

Wide Range of Material Selection |

Wide voltage window with good stability at high voltages |

Reduces interfacial side reactions, expanding the range of anode and cathode materials, and lowers raw material costs and resource scarcity risks |

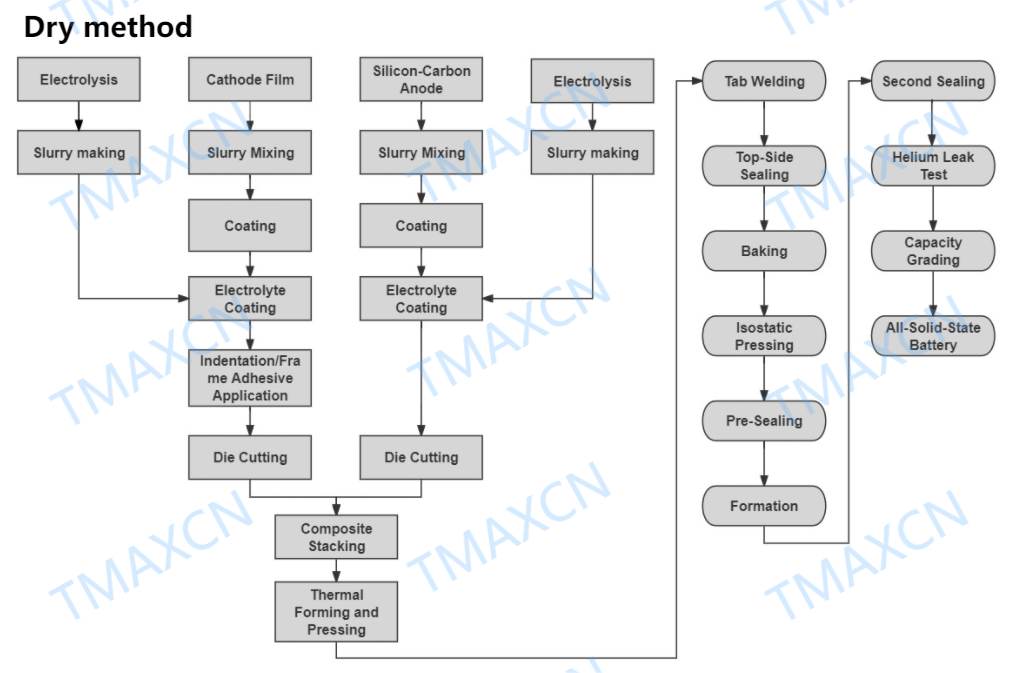

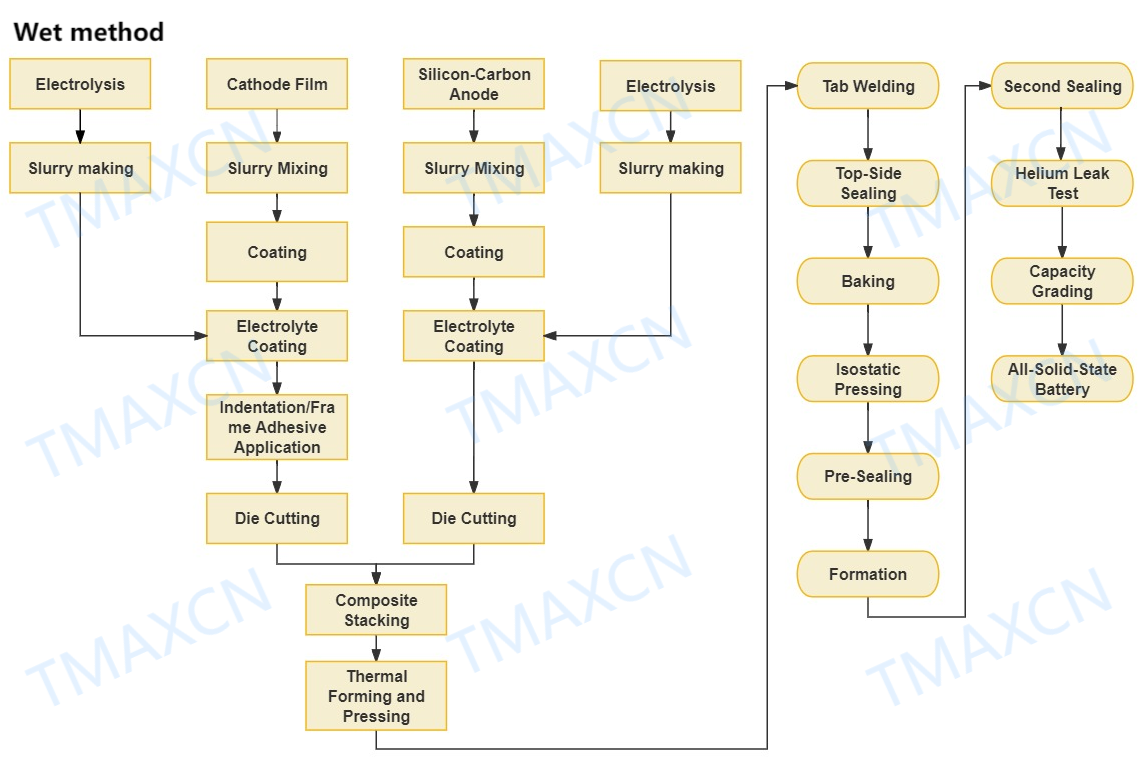

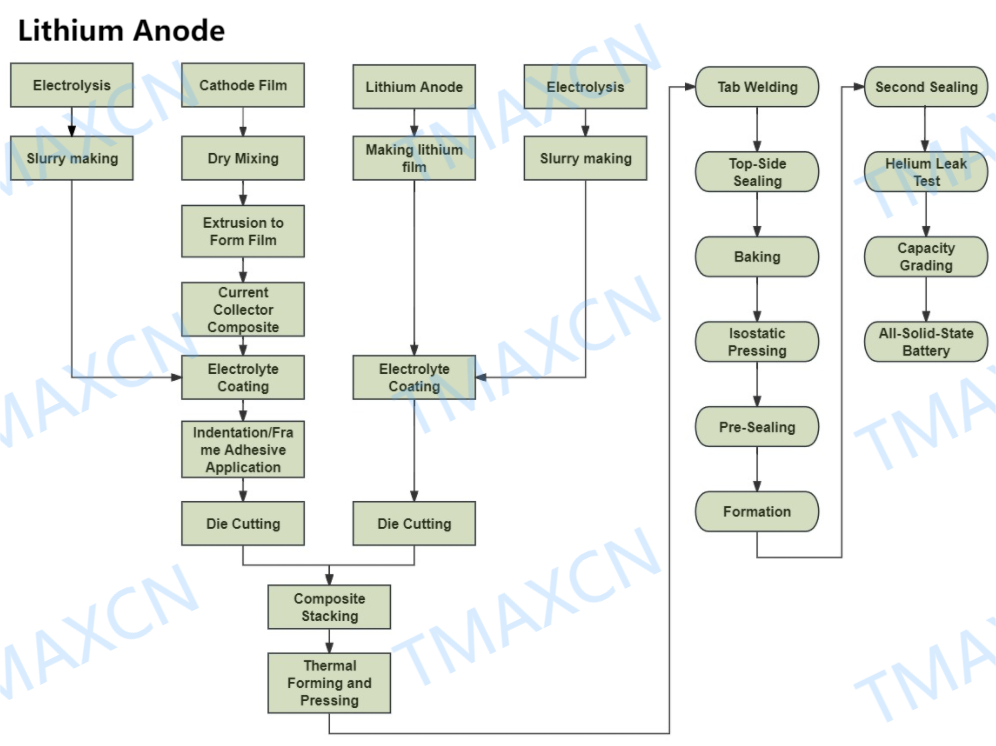

Technical process(just for reference)

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975