ItemNo :

LITH-WS-5V6A32CHMOQ :

1Compliance:

CE CertifiedWarranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com

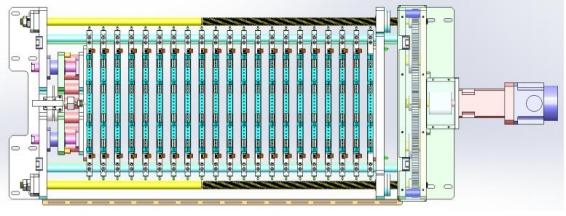

Equipment Function and Principle

This equipment is used for cell formation and hot pressing, replacing existing formation fixtures and hot press machines. The main operations include manually loading the material from the preparation tooling into the hot press formation fixture, automatic heating, pressing, and formation, and then manually unloading from the hot fixture after the formation process. This equipment is suitable for specific battery production (user provides drawings), compatible with cells with or without airbag indentations, and consists of two sets of hot press fixtures.

System Features

1. The system adopts an intelligent and user-friendly design with multi-stage pressure adjustment, allowing pressure change over time.

2. One-click pressure setting: input the length and width of the cell, and the program automatically generates pressure and stress.

3. Temperature is controlled by a temperature module, with real-time data feedback via K-type thermocouple to PLC. Temperature rises from ambient to 90°C in less than 45 minutes with an error margin of ±1.5°C.

4. The temperature control module monitors and controls heating. Heating automatically starts when below the set temperature and stops when above. A second-level high-temperature alarm stops the entire fixture's heating and formation process if the temperature exceeds the maximum, prompting system alarms for manual intervention. Multiple monitoring pathways ensure redundancy, with at least two parallel monitors providing independent alarm signals in case of heating issues.

Incoming Material Specifications and Adaptation Range

|

Specification |

Max |

Min |

|

Cell Length (excluding tabs, mm) |

160 |

50 |

|

Cell Width (excluding airbag, mm) |

100 |

50 |

|

Cell Thickness (mm) |

12 |

4 |

|

Airbag Width (mm) |

200 |

50 |

|

Tab Length (mm) |

25 |

15 |

|

Tab Width (mm) |

35 |

3 |

|

Tab Center Distance (mm) |

50 |

10 |

Technical Parameters

|

Category |

Details |

|

Charging Current Range (mA) |

10~6000 |

|

Current Measurement and Control Accuracy (mA) |

±(0.05%RD+0.05%FS) |

|

Current Resolution (mA) |

1 |

|

Voltage Measurement Range (mV) |

0-5000 |

|

Voltage Measurement and Control Accuracy (mV) |

±(0.05%RD+0.05%FS) |

|

Voltage Resolution (mV) |

1 |

|

Constant Voltage Charging Range (mV) |

2500~4500 |

|

Minimum Discharge Voltage (mV) |

2000 |

|

Time Measurement Range and Accuracy |

3000 minutes/step, accuracy ±0.1% |

|

Failure Rate |

≤1%, channel utilization rate ≥99%. |

|

Electrical Specifications |

Voltage: AC380V±10%, installed power: 12KW (including heating plate and motor power). |

|

Circuit Connection |

Terminal connection between fixtures and charging equipment. |

|

Temperature Control Range |

Ambient temperature to 90°C. |

|

Design |

Specially designed according to battery performance requirements, suitable for battery formation and sorting/testing equipment. |

|

Modular Manufacturing |

Strong versatility and easy maintenance. Heating and non-heating parts are installed separately for good heat dissipation and stable system operation. |

|

Cell Placement Direction |

Cells upright, airbags facing upwards |

|

Equipment Failure Rate |

<1% |

|

Channel Utilization Rate |

> 99% |

|

Number of Fixture Layers |

16 |

|

Total Fixture Quantity |

1 |

|

Cells per Layer |

2 |

|

Total Number of Cells |

32 |

|

Pressure Source |

Motor + Reducer |

|

Pressure Range |

200~3000 Kgf |

|

Transmission Mode |

Lead Screw |

|

Pressure Control Accuracy |

200-1000 kg: ≤±20 kg; 1000-3000 kg: ≤±2% RD |

|

Motor Power |

2 KW |

|

Holding Time |

1s--300min (adjustable) |

|

Heating Method |

Silicone Heating Plate |

|

Heating Time |

Initial heating time ≤30 min (from room temperature to 90°C); continuous production without reheating wait time |

|

Temperature Control Method |

Temperature monitoring on each layer |

|

Adjustable Temperature Range |

Room temperature ~ 90°C |

|

Interlayer Temperature Deviation |

±1.5°C |

|

Pressure Control |

PLC control, multi-time segment, multi-stage pressure change settings |

|

Heating Plate Thickness |

2.0 mm |

|

Fixture |

Special fixture |

|

Storage Environment Temperature |

5 ~ 45°C |

|

Cabinet Outer Wall Temperature |

Not exceeding 40°C |

|

Current and Voltage Testing Method |

Four-wire measurement, PCB board pressing mode |

|

Operating Power Supply |

AC380V, 3Φ, 50Hz, requires reliable independent grounding |

|

Equipment Weight |

Within 1200 kg |

|

Factory Load Capacity |

Total weight to load area ratio ≤600 kg/M² |

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975