ItemNo :

LITH-111A-DMOQ :

1Warranty:

2 yearsDelivery Time:

5 daysEmail :

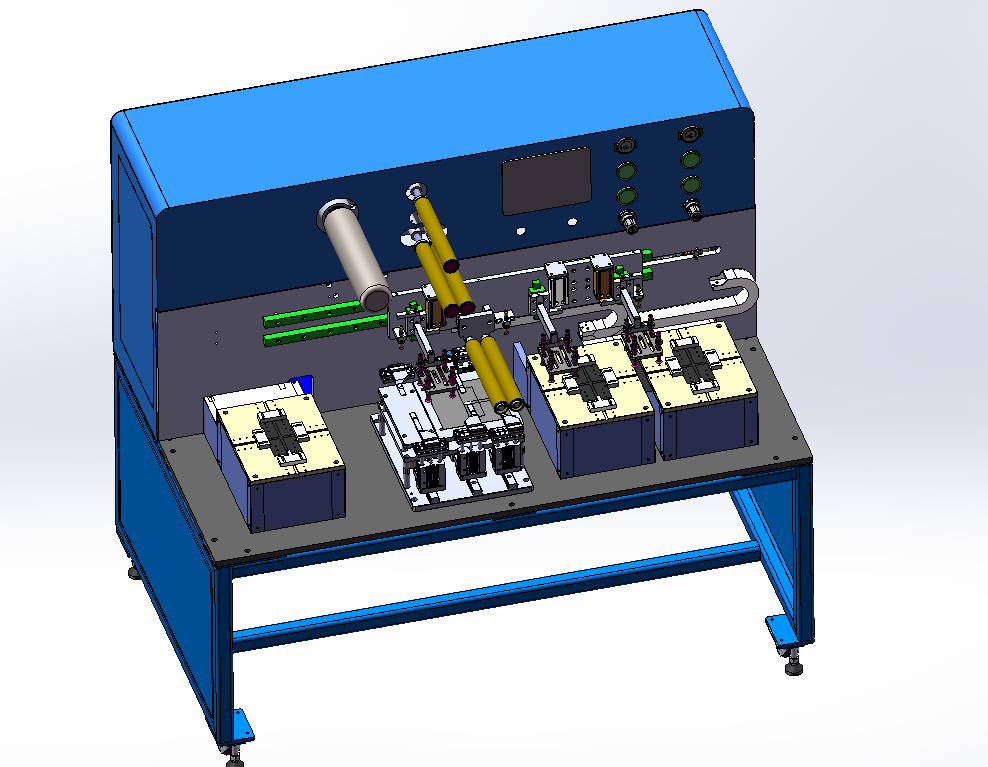

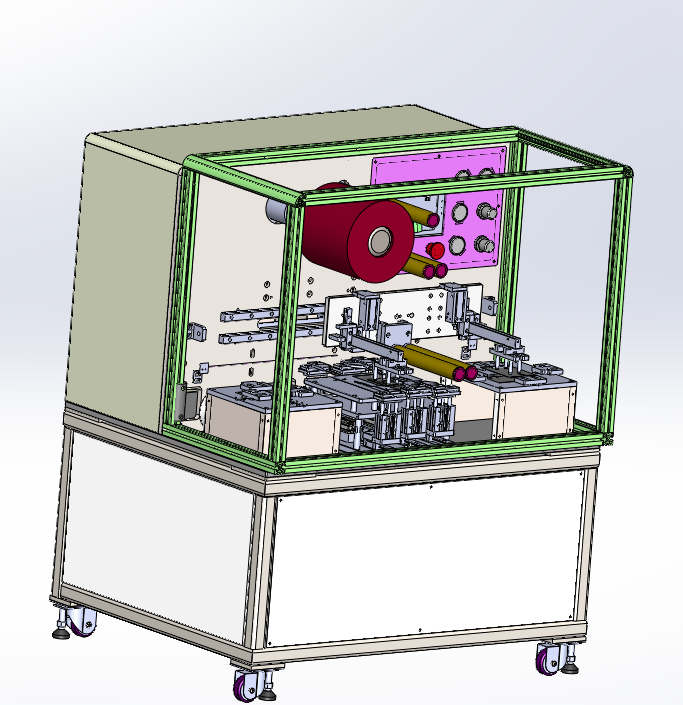

Louis@lithmachine.comAutomatic Stacking Machine With Three Magazines For Solid State Battery Production

The LITH-111A-D is primarily used for the Z-fashion stacking assembly of cell electrodes and solid electrolyte. This equipment enables manual loading of pieces, by fully automatic alignment and stacking processes, offering high stacking efficiency and precision. It is designed to stack battery cells up to 160*160/300*300mm, with adjustments available for different sizes via interchangeable fixtures, making it highly suitable for the development and sample production of stacked solid state battery. The equipment features a single-arm structure, automatic constant tension control for the separator roll, and automatic correction control.

Features

*The number of stacking layer can be automatically controlled according to the preset;

*The compatibility design is adopted, and the change of battery size can be realized by adjusting the positioning fixture, with a large adjustment range;

*PLC control, HMI operation, easy to use and maintain;

*Electrode manual loading, automatic positioning, manipulator automatic suction and automatic stacking;

*Separator automatic servo constant tension control.

*Separator automatic photoelectric correction control.

Technical parameters

|

Working Voltage |

AC220V/110V, 50/60Hz |

|

Power |

0.6kw |

|

Stacking mode |

Z fashion |

|

Operation mode |

Manual feeding, manipulator picking up electrodes automatically, automatic separator pulling |

|

Stacking accuracy |

≤±0.3mm |

|

Stacking size range |

Min.L40mm *W40mm, Max. L160mm*W160mm(standard) Larger compatible size is available upon request at extra cost |

|

Stacking thickness |

Max.10mm |

|

Number of stacking |

Max. 100 layers adjustable |

|

Separator coil diameter |

Max. 250mm |

|

Separator core |

3-inch roll core, air expansion shaft clamping |

|

Tension control |

Automatic servo constant tension control |

|

Separator correction |

Automatic photoelectric correction control |

|

Machine dimensions |

L1000mm*W780mm*H750mm |

|

weight |

About 400Kg |

|

Gas source |

0.5~0.8MPa compressed air |

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975