ItemNo :

LITH-SCK200MOQ :

1Warranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com

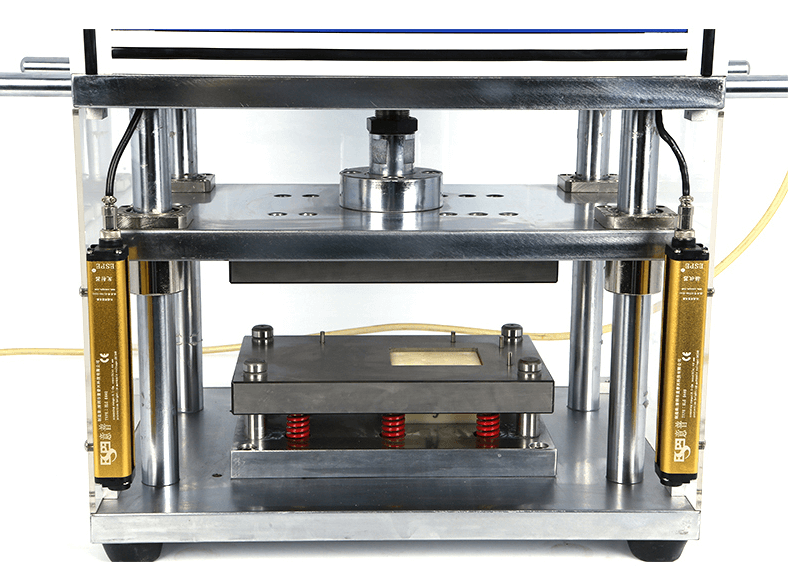

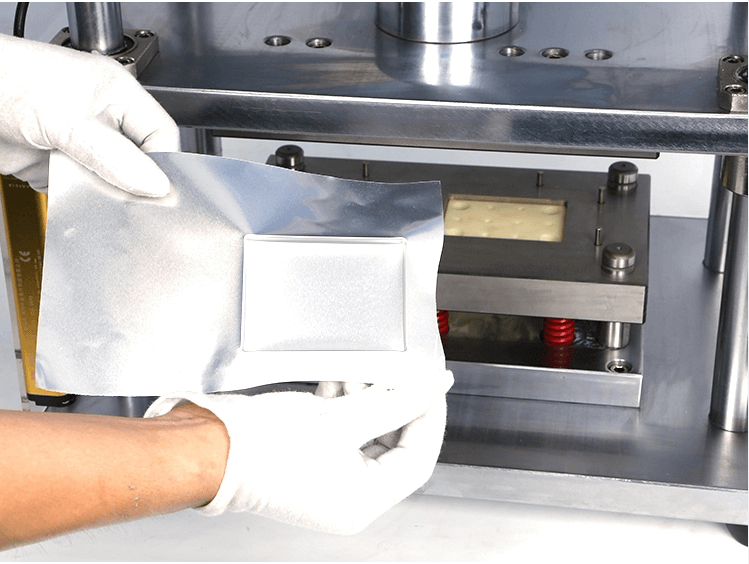

LITH-SCK200 is a CE Certified pouch cell forming machine used in the production line of making pouch cell batteries with optional size range. It is used to prepare polymer cases made of Aluminum Laminated Films. To ensure continuity and compatibility for customer's research, adjustable depth (spacers is included in standard package) to directly match the electrodes cut by electrode cutting machine.

1 LITH-SCK200 Battery Pouch Forming Machine is used for lithium polymer battery/ pouch cell cup forming in the of making pouch cell batteries.

2 The machine is used to prepare polymer cases made of Aluminum Laminated Films.

3 This lab aluminum laminated film pouch forming machine is designed with simple Spring mold with a customized size, which is more suitable for lab research.

If you need a bench top mini forming machine, please choose the LITH- MSK-PN120 model

|

Model |

Lab Polymer Battery Pouch Forming Machine LITH-SCK200 |

|

Source voltage |

AC 220V/110V, 50/60HZ |

|

Power |

100W |

|

Warranty |

Two years limited warranty with lifetime support |

|

Advantages |

1 Structure of guide pin, slide up and down smoothly with high precision 2 Change mould, adjust tensile depth simply, quickly 3 Use screen and casing protection, guarantee safety 4 High strength of chrome steel and aluminum alloy, surface roasts the paint processing through environmental protection electroplating |

|

Suitable aluminum film thickness |

0.1-0.2mm |

|

Suitable mold size |

Customized as customer's request, with punching depth ≤24mm |

|

Max. Cup Depth |

Single pit punching depth ≤24mm |

|

Output |

200-400EA/H |

|

Output pressure |

5T |

|

Air source |

0.5-0.7MPa |

|

Mold materials |

SS136 Die steel |

|

Dimension (L*W*H) |

460*320*925mm |

|

Weight |

About 130kg |

| Recommendation |

For the pouch cell assembly, we also recommend you the following items: Forming machine Hot sealer with tab Vacuuming sealer Ultrasonic tab welder Die Cutter Aluminum Laminated Film |

![]()

Pouch Cell Process: Tube Furnace/ Muffle Furnace→ Vacuum Mixing→ Electrode Coating→ Roll press→ Electrode Cutting→ Vacuum Drying→ Cases Forming→ Top&Side Sealing→ Electrolyte Filling→ Vacuum Sealing→ Battery Analyzer

For the pouch cell assembly, we also recommend you the following items:

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975