ItemNo :

LITH-JSMOQ :

1Warranty:

2 yearsDelivery Time:

5 daysEmail :

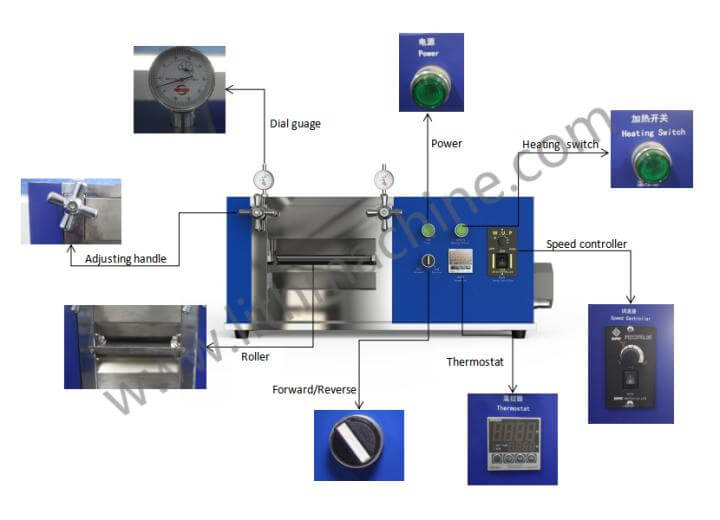

Louis@lithmachine.comSodium-ion Battery Heat Rolling Press Machine For Na-ion Cell Electrode Calender

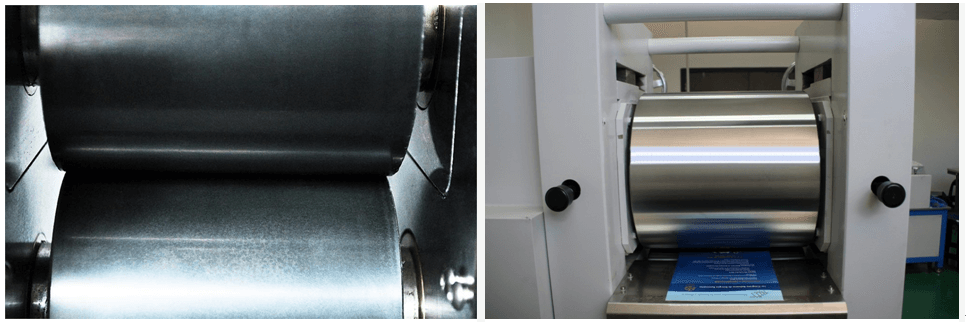

This type of roller press is specially used for electric rolling of small lithium electrode sheets, a small amount of precious metal materials such as gold and silver, copper and aluminum, and other non-ferrous materials. It is especially suitable for thinning and increasing density of lithium battery plate, which is a clean energy material. The machine adopts gear drive to realize roll pressing. The rolling thickness can be adjusted and used conveniently. It can realize percentile meter to directly control the material pressing thickness.

SPECIFICATIONS

Model

LITH-JS

Working Power

2400W

Voltage

220V/110V selectable

Effective Calendering Width

100-400mm selectable

Roller Size Optional

100mm Dia. x 100mm W

100mm Dia. x 200mm W

100mm Dia. x 300mm W

100mm Dia. x 400mm W

Or customized roller diameter and rolling width

Hardness of roll surface

HRC62, imported 9CR2MO steel roll material

Calendering Thickness

(Effective clearance)

0~3 mm adjustable

Dial Gauge Accuracy

0.01mm

Rolling Speed

CVT, linear speed 0-8.5 m/min adjustable

Roller SurfaceFinish Degree

Roll surface quenching depth

5mm

Max. Pressure

5Ton

Heating Temperature

· 150°C Max. (< 1hr)

· 130°C Continuously

· Recommended Heating Rate: 1.3°C/minute

The heating temperature can be customized

Temperature Control Accuracy

+/-1°C

Hard chromium plating never rusts

Operation environment

Ar gas compatible

![]()

Pouch Cell Process: Tube Furnace/ Muffle Furnace→ Vacuum Mixing→ Electrode Coating→ Roll press→ Electrode Cutting→ Vacuum Drying→ Cases Forming→ Top&Side Sealing→ Electrolyte Filling→ Vacuum Sealing→ Battery Analyzer

For the pouch cell assembly, we also recommend you the following items:

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975