ItemNo :

LITH-MQ300MOQ :

1Compliance:

Warranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.comLab Electrode Die Cutter For Solid State Battery Production

1.Speedy,efficiently

2.for current collector tabs

3.One stop serives,full solutions

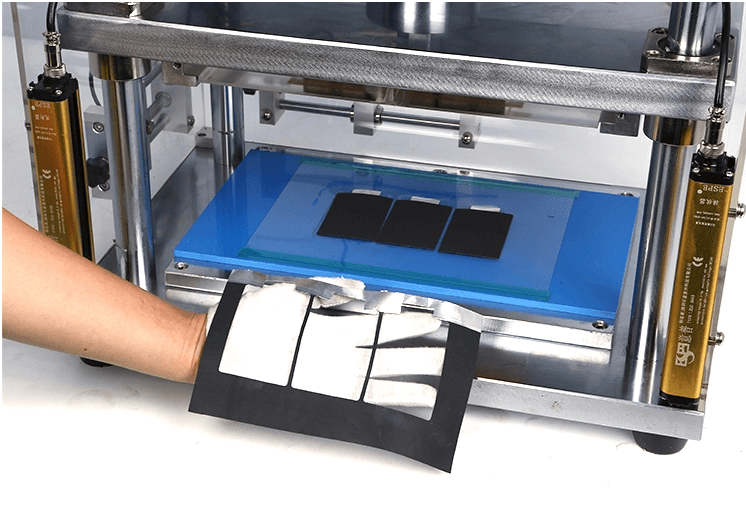

LITH-MQ300 is a CE Certified semi-automatic electrode die cutter.It is a necessary tool in the production ,line of pouch cell to produce specific shapes of cathodes and anodes with current collector tabs.

|

Model |

LITH-MQ300 |

|

Working Table Area |

300mm(L) x 250mm(W) OR 400mm(L) x 400mm(W) |

|

Die Set Dimensions |

81mm (L) x 49mm (W) with current collect included |

|

Working Voltage |

220V 50/Hz, single phase |

|

Max. Power Consumption |

10W |

|

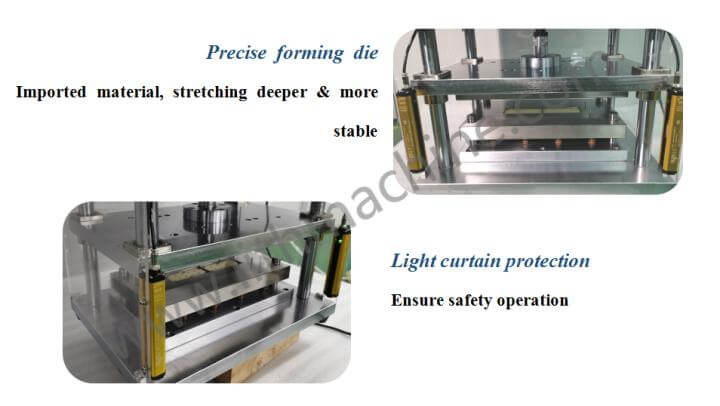

Safety Sensor |

Built in IR sensor (Safety Curtain) to protect against hand injuires during electrode feeding |

|

Cutting Accuracy |

±0.1mm |

|

Air Cylinder |

3 tons Max. pressure |

|

Tensile Cylinder |

0.15 tons pressure |

|

Feeding |

Manually |

|

Production Yield |

800 - 2000 pieces of electrodes per hour |

|

Compliance |

CE Certified |

|

Warranty |

One Year limited warranty with lifetime support |

|

Air Pressure |

recommend 60 psi (Air compressor is not included) |

|

Product Dimensions |

550mm(L) x 450mm(W) x 900mm(H) |

|

Net Weight |

120kg (265 lbs) |

|

Apply |

for pouch cell electrode sheet |

![]()

Pouch Cell Process: Tube Furnace/ Muffle Furnace→ Vacuum Mixing→ Electrode Coating→ Roll press→ Electrode Cutting→ Vacuum Drying→ Cases Forming→ Top&Side Sealing→ Electrolyte Filling→ Vacuum Sealing→ Battery Analyzer

For the pouch cell assembly, we also recommend you the following items:

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975