ItemNo :

LITH-HSC-SMOQ :

1Port :

Xiamen PortCompliance:

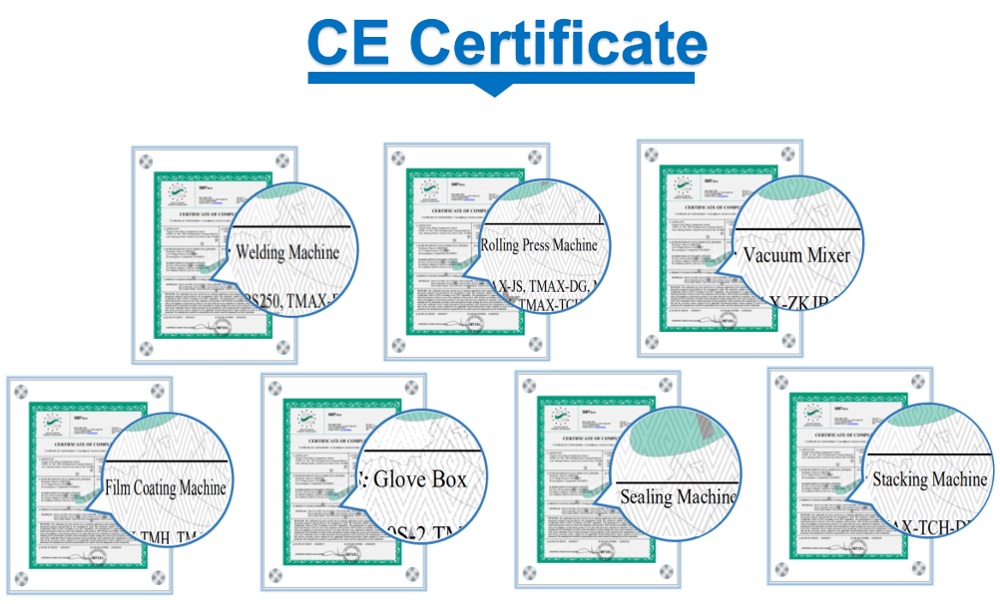

CE CertifiedWarranty:

1 Year limited warranty with lifetime supportDelivery Time:

Email :

Louis@lithmachine.com600KN Automatic Continuous Transfer Belt Four Column Beam Press Cutter Machine For Carpet Die Cutting

Application and characteristics

1. This machine is suitable for large factories to use molding die to carpet, leather, rubber, cloth and other non-metallic materials for continuous mass blanking operations

2. The conveying part is controlled by PLC, the material is input from one side of the machine by servo motor, and output from the other side after die cutting to ensure accurate feeding and smooth running; And the feeding length can be easily adjusted through the touch screen.

3. The main machine adopts four-column guide, double crank balance, four-column block fine-tuning mechanism, hydraulic system control, to ensure the speed and accuracy of the machine die cutting, all the sliding connection parts adopt central oil supply automatic lubrication device, so that the wear is minimized.

4. The input and output of materials are transported on the conveyor belt, and the die-cutting and punching of materials are also automatically completed on the conveyor belt.

5. Photoelectric pneumatic correction device is used to ensure the accuracy of the conveyor belt operating position.

6. The feed and discharge ports in the cutting area of the machine are equipped with safety light curtains to ensure the personal safety of the operator.

7. Pneumatic clamping device is used to fix the tool die, and the replacement of the tool die is convenient and fast.

8. Special specifications can be customized.

Main technical parameters:

|

Maximum cutting force |

400KN |

600KN |

|

Cutting area (mm) |

1250*800 |

1250*1200 |

|

1600*1200 |

||

|

Width (mm) |

25-135 |

25-135 |

|

Main motor power |

4KW |

5.5KW |

|

Weight (kg) |

5000 |

7500 |

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975