ItemNo :

LITH-S1X-512/3AMOQ :

1Compliance:

CE CertifiedWarranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com

Features:

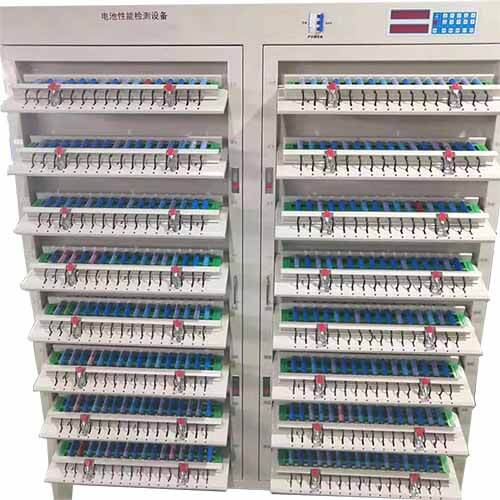

1. Each device can carry out constant current and constant voltage charging and constant current discharge test on 512 batteries meeting the voltage range.

2. Adopt the constant current constant voltage power supply of the invention patent, constant current to constant voltage switching without impact, especially suitable for the charging requirements of lithium-ion battery.

3. The AVR single-chip computer is used as the control center of the equipment, and the peripheral sampling circuit is used. The equipment can be controlled by the superior computer. When the computer is connected, the complete charge discharge curve of all channels can be saved, or it can be separated from the superior computer. Through the operation of the control panel, the constant current and voltage charging, constant current discharge test, time sorting and other work can be completed.

4. Each battery has an independent constant current and voltage source, and the self-made circuit does not affect each other.

5. Detect the voltage of each battery in real time. When charging, charge at constant current first. When the battery voltage reaches the set value, it will smoothly switch to constant voltage charging. When the set time or current termination conditions are met, the charging will end. During constant current discharge, when the battery voltage is lower than the set value, the discharge is ended and the corresponding battery indicator light is on.

6. It has the function of power-off protection, and can continue to operate after receiving the original workflow

7. The power tube is 50N06, which is suitable for batteries requiring low discharge voltage, such as lithium iron phosphate battery

8. The upper computer can set 32 working step parameters and 256 cycles, and each upper computer can be connected with 1-10 sets of single-chip system (less than 10 sets are recommended).

Supporting Software Functions:

A) Graphic operation interface is used to display the data of voltage, current, time and capacity of each battery, and display the corresponding working status and abnormal conditions in various colors;

B) Battery capacity indication of any section (up to 100 sections);

C) Data points can be recorded according to the change conditions of voltage, current and time to form a complete charging and discharging curve data, and the time interval of curve data points is ≤ 4 Second;

D) Carry out battery sorting function under various conditions (capacity, time, open circuit voltage, discharge platform, etc.);

E) Automatically calculate constant current charging ratio, capacity loss, discharge efficiency, average voltage, median voltage and other data;

F) Set operator authority and operate in different levels;

Display charge discharge curve and cycle chart;

Main Technical Parameters

|

Number of Device Channels |

The whole machine has 512 channels in total |

|

Workflow Control Mode |

Whole cabinet control |

|

Charging Mode |

Constant current and constant voltage |

|

Charging Cut-off Conditions |

Voltage, current, time, capacity |

|

Discharge Mode |

Constant current |

|

Discharge Cut-off Conditions |

Voltage, time and capacity |

|

Sampling Inspection Cycle |

≤10s |

|

Voltage Measurement Range |

0 ~ 5V, resolution 1mV |

|

Battery Voltage Range |

Charging: 0 ~ 4.5V, Discharging: 4.5 ~ 2.0V |

|

Constant Voltage Range |

3~4.5V |

|

Voltage Accuracy |

±(0.05%RD+0.1%FS) |

|

Current Range |

Charge: 0.015-3A, Discharge: 0.015-3A, Resolution: 1mA |

|

Current Accuracy |

±(0.1%RD+0.1%FS) |

|

Time Frame |

Any setting within 0 ~ 30000 minutes, time unit is min |

|

Time Accuracy |

≤±0.1% |

|

Fixture Type |

Cylindrical four wire fixture |

|

Fixture Adjustable Height |

0~90mm |

|

Support Battery |

Cylindrical and small square aluminum shell |

|

Working Power Supply |

AC380V±10%, 50HZ, Power consumption≤13kw(three-phase four wire system) |

|

Communication Mode |

RS485, baud rate 57600 |

|

Overall Dimension |

1440mm(Width)*500mm(Deep)*1800mm(High) |

|

Work Environment |

Temperature: 0-40 ℃, relative humidity ≤ 85% RH |

|

Full Load Operating Current |

The maximum phase line is 30A, and the maximum zero line is 3A |

|

Equipment Starting Current |

The closing moment of air switch is about 60A |

|

Machine Weight |

About 250 kg |

![]()

Power Processing→Power Grinding→Vacuum Mixing→Electrode Coating→Roll Press→Sheet Cutting→Vacuum Drying→Ultrasonic Welding→Electrode Winding→Spot Welding→Grooving→Glove Box→Electrolyte Injection→Electrode Diffusion→Hydraulic Sealing→Battery Analyzer

Related Machine

Electrode Slitting

Welding Power:

80-6500W optional

Lab cylindrical cell grooving machine

Manual Sealing or Pneumatic Sealing Machine

8 Channel Battery Tester

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975