Furnace structure

|

-

Furnace, two temperature controllers, two-channel gas flowmeters are integrated into a mobile aluminum alloy frame.

-

The chamber is made of high purity fused quartz tube with dimesion of 11" OD/10.8" ID x 9" H.

-

The vacuum flanges are made of Stainless Steel 316 and lifting by electric motor.

-

Two 5"x5" IR heating plates and the spacing are adjustable .

-

Top sample holder is rotatable at the speed 0 - 7 RPM.

|

|

|

-

Top Flange with one KFD-25 vacuum port and one gas outlet (1/4" pipe required) can slide up or down manually to load and unload substrate and evaporated material easily.

-

Bottom flange has one KFD-25 vacuum port with one gas inlet (1/4" pipe required) with needle valves.

-

The flange is sealed by double silicone o-rings and can achieve max. the vacuum pressure of 10E-2 Torr by a quality mechanical pump and 10E-5 Torr by a molecular pump (vacuum pump is not included, please order separately).

-

One digital vacuum gauge is installed on the top flange.

-

Precision anti-corrosion digital vacuum gauge is in standard package(Since 2016.03.24).

|

Heater and Sample Holder

|

-

Two independently controlled heaters with manually adjustable gap from 2 - 30 mm.

-

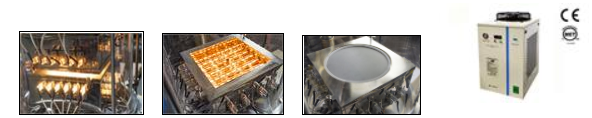

20 pcs Halogen lamps are used as the heating element for rapid thermal processing.

-

Heaters are made of stainless steel with water cold jacket to reduce heat radiation and are capable of fast cooling.

-

5" Dia. the circular wafer holder is built into the top heater for holding the substrate.

-

One set of high thermal-conductive AlN plates (5" Dia. x 0.5mm Thick) are included (place on the back of the substrate to make it heat uniformly).

-

A 58L/min circulating water chiller is included for saving water source ( click the picture below to see detailed specs).

-

Top sample holder is rotatable at adjustable speed 0 - 7 RPM

|

Temperature Controller

|

-

Two precision digital temperature controllers with 30 segments programmable offer independent controlling of top and bottom heaters.

-

Each controller has a PID autotune function to protect heaters from overshooting and an alarm function to prevent overheating from damaging the thermal couples.

-

PC communication interface & software are installed for (click the picture below for details) recording temperature profile shown as below.

-

|

Working Temperature

|

-

Maximum temperature for each heater: ≤ 800ºC.

-

Maximum temperature difference between two heaters: ≤ 300ºC depends on the spacing between two heaters:

-

Spacing 30mm Max. temp difference: 315ºC @ heating bottom only

|

|

Heating & Cooling Rate

|

-

Heating: < 8ºC/s ( heating single heater only )

-

Cooling: < 10ºC/s (600 - 100ºC) Max.

|

|

Thermal Couple

|

Two K-type thermal couples are installed on top and bottom heaters separately.

|

|

Working Voltage

|

208 - 240VAC, single phase, 50A air breaker

|

|

Power Requirement

|

10 KW total

|

Shipping Weight & Dimension

|

-

Two pallets: 525 lbs and 48" x 40" x 87" and 165 lbs with 39x31x29" dimension

|

Optional

|

-

One vacuum pump is required. Please order separately by clicking the first picture from the left below. Vacuum level can reach ≤ 10E-2 torr by mechanical pump.

-

If using corrosive gas, please use a cold trap or anti-corrosive dry pump is shown in the picture 2-3 at extra cost.

-

You may choose digital MFC gas delivery system by clicking the first picture from the right below.

|

|

Warranty

|

One year limited with lifetime support ( Consumable parts such as quartz tube and heating lamps are not covered by the warranty).

|

Application Notes & Warnings

|

-

The tube furnaces with quartz tube are designed for using under vacuum and low pressure < 0.2 bars / 3 psi / 0.02 Mpa. Vacuum pressures may only be safely used up to 1000°C. The flow rate for gasses should be limited to < 200 SCCM (or 200 ml/min) for reducing thermal shocks to the tube.

-

Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation.

-

The foot-stand of this furnace is designed for short distance hauling on the even surface (without pits or bumps) only.

|

![]()

![]()

![]()

![]()

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975