|

Feature

|

-

Specially Designed for coating conductive gold film for SEM sample

-

Compact plasma sputtering coater designed for metallic coatings, such as gold, platinum, and silver

-

One 2" gold (4N) target is included

|

|

Input Voltage

|

-

220 VAC 50/60Hz, 200W

-

< 1000 W (including vacuum pump power)

-

110VAC power is available by using a 1000 W transformer (15 A fuse). The transformer is sold separately

|

|

Output Voltage

|

|

|

Sputtering current

|

-

0 - 50 mA (max.) adjustable sputtering current

-

Digital current meter (mA)

-

Over-current protection

|

|

Sputtering time

|

-

1 -120 seconds adjustable

|

|

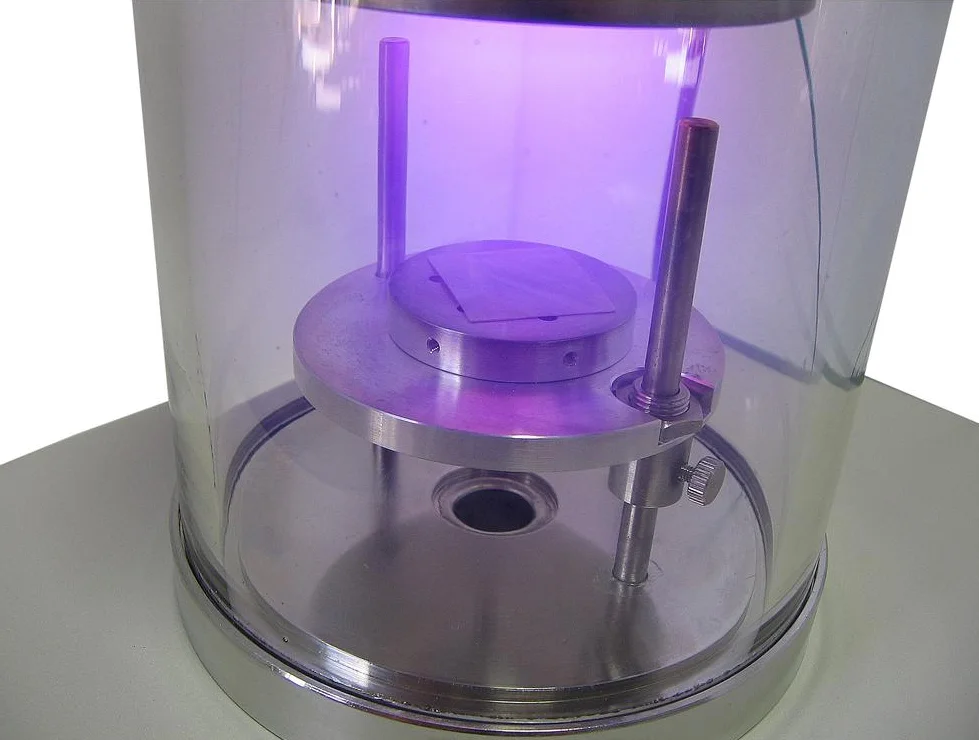

Specimen Chamber

|

-

Quartz glass tube, 165 mm OD. x 150 mm ID x 150 mm Height

|

|

Specimen Stage

|

-

2" diameter

-

height adjustable, 30 - 80 mm from the sample to the target

|

|

Sputtering Head

|

-

2" magnetron sputtering head

-

One manually operated shutter for target protection

|

|

Vacuum Pressure

|

-

Digital vacuum pressure meter (Pa)

-

KF25 vacuum pump connector

-

Ultimate vacuum pressure 1 Pa by the mechanical pump. The Pump is not included

|

|

Vacuum pump (optional)

|

-

The double stage rotary vane pump EQ-FYP is recommended.

-

Optional: you may use a turbo pump to achieve 1.0E-5 Torr vacuum by a turbo pump (Click the bottom right picture)

|

|

Input gas

|

-

One 1/4 Swagelok type tube fitting is installed for connecting the inert gas cylinder

-

One metering valve is in the front panel for adjusting the input gas

|

|

Target

|

-

One 50mm Dia. x 0.12mm gold target is included

-

4N purity gold foil: 50 mm(2 inch) Dia. x 0.12 mm (Included and pre-installed on coater)

-

Optional Targets are available

-

Au target (50 mm Dia. x 0.12 mm, 4N purity)

-

Pt target (50 mm Dia. x 0.12 mm, 4N purity)

-

Ag target (50 mm Dia. x 0.5 mm, 4N purity)

This model is suitable for coating Gold, Silver, and Platinium. It is not suitable for coating light metallic material such as Al, Mg, Zn, or Carbon target due to low energy. Please consider our high power DC/RF magnetron sputtering coater or thermal evaporation coater.

|

|

Product Dimension and weight

|

-

460 mm (L) × 330 mm (W) × 520 mm (H)

-

20kg

|

|

Shipping Weight & Dimension

|

|

|

Compliance

|

-

CE Certified

-

Ready to pass UL/CSA certification at extra cost.

|

|

Warranty

|

-

One year limited with lifetime support

|

|

Application Notes

|

-

For the best film-substrate adhesion strength, please clean the substrate surface before coating:

-

Ultrasonic cleaning (Click the picture below to order) with the following sequential baths - (1) acetone, (2) isopropyl alcohol - to remove oil and grease. Blow dry the substrate with N2, then hot bake in vacuum to remove absorbed moisture

-

Plasma cleaning (Click the picture below to order) may be needed for surface roughening, surface chemical bonds activation, or additional contamination removal

-

A thin buffer layer (~5 nm), such as Cr, Ti, Mo, Ta, could be applied to improve adhesion of metals and alloys

-

A two-stage pressure regulator (not included) should be installed on the gas cylinder to limit the output pressure of gas to below 0.02 MPa for safe usage. Please use > 5N purity Ar gas for plasma sputtering

-

The sputtering coater can be placed into an Ar and N2 gas glove box for coating

-

Please multiple coating to increase coating thickness, please let the machine cool down for serval minutes between each use since it does not have water cooling

-

HIGH VOLTAGE! Sputtering heads connect to high voltage. For safety, the operator must shut down the equipment before sample loading and target changing operations

-

This model is not suitable for coating light metallic material such as Al, Mg, Zn, or Carbon target due to low energy. Please consider our magnetron sputtering coater or thermal evaporation coater. (Click pictures below for detail)

|

![]()

![]()

![]()

![]()

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975