ItemNo :

LITH-SQMMOQ :

1Warranty:

Two years limited warranty with lifetime technicalDelivery Time:

5 daysEmail :

Louis@lithmachine.com

Laboratory Compact Stirred Ball Mill Equipment

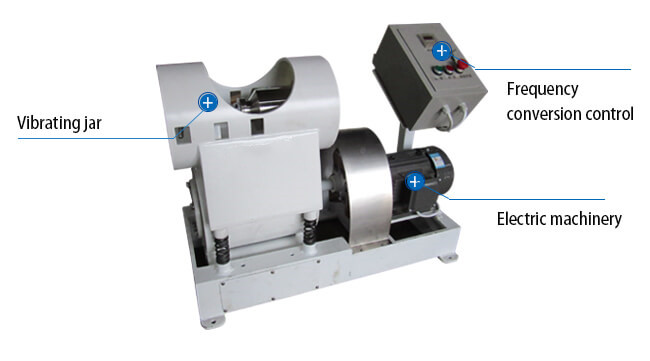

Vibration ball mill is a new model of powder equipment with high efficiency, including three models of single jar, double jars and three jars. It’s easy and convenient to operate, reliable to work, easy to clean, adaptable to different working condition. it can be used for wet and dry grinding without pollution. The machine is widely used in the field of electronics, ceramics, chemicals, powder metal, tungsten, Calcium carbide, rubber compounds, magnetic materials and high-frequency porcelain material and pharmaceutical of radio industries. Liners in materials of stainless steel, ceramic, zirconia, glazed block, nylon, PTFE, food-standard rubber and polyurethane are available for customer’s option.

Vibration ball mill consists of shelf, under-frame, vibration generator, spring, cylinder, motor and so on. When the machine starts up, the motor drives the vibration generator to make continuous vibration, which makes cylinder doing small amplitude and continuous movement with high frequency. Because of self rotation and relative movement of the grind media, the materials inside the cylinder are frequently crushed, stripped and ground into uniform powder.

Feature

1.It has larger capacity than other ball mills.

2.It has simple

structure. the machine produces different powder in different

granularity by means of adjusting vibrating amplitude, frequency, grind

media and match ratio.

3.Vibration mill with jacket makes grinding temperature adjustable.

4.Vibration with griddle and collection device can work continuously.

5.Easy and convenient to be operated, reliable at performance, easy to clean, strong ability to adapt to any working conditions.

6.No environmental pollution can be dry, wet milling.

7.Light weight, small size, high efficiency

8.customized order is acceptable.

Application Cases of Planetary Ball Mill

Application Cases of Planetary Ball Mill

|

Parameter of Vibration Ball Mill |

||||||||

|

Type |

Jar |

Load |

Motor |

Material of |

Feed |

Output |

Category |

Power |

|

Volume(L) |

Capacity(L) |

Power(KW) |

Grinding Barrel |

Size(mm) |

size(μm) |

Supply |

||

|

ZM-1L |

1 |

0.5 |

1.1 |

Stainless steel |

≤5 |

≤1 |

Lab scale |

380V |

|

ZM-2L |

2 |

1 |

1.1 |

≤5 |

≤1 |

380V |

||

|

ZM-3L |

3 |

1.5 |

1.1 |

≤5 |

≤1 |

380V |

||

|

ZM-5L |

5 |

2.5 |

1.1 |

≤5 |

≤1 |

380V |

||

|

ZM-10L |

10 |

5 |

1.5 |

≤10 |

≤1 |

Light Type |

380V |

|

|

ZM-15L |

15 |

7.5 |

1.5 |

≤10 |

≤1 |

380V |

||

|

ZM-20L |

20 |

10 |

1.5 |

≤10 |

≤1 |

380V |

||

|

ZM-50L |

50 |

25 |

3 |

Carbon steel and |

≤10 |

≤1 |

380V |

|

|

ZM-100L |

100 |

50 |

4 |

≤20 |

≤1 |

Large Type |

380V |

|

|

Materials of Jars(1-20L): Stainless steel, agate, nylon, corundum, zirconia, PTFE. |

||||||||

|

Materials of Jar(30-200L): Carbon steel, stainless steel. Optional liners have nylon, PU, PTFE, corundum. |

||||||||

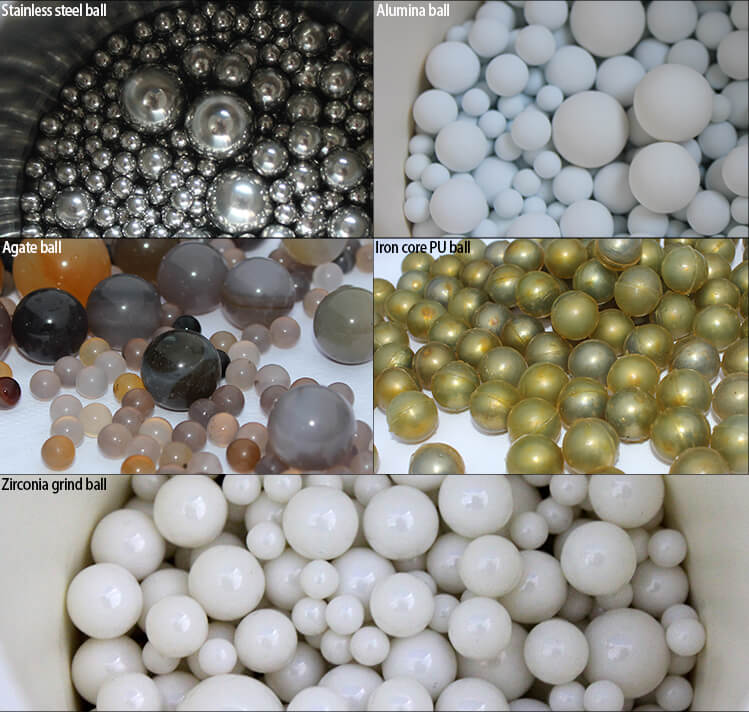

Besides the planetary ball mill machine, our factory provides all kinds of mill pots,like stainless steel mill pot, zirconia mill pot, alumina mill pot, nylon mill pot, PU mill pot, tungsten mill pot, hard metal mill pot and tempered nylon mill pot etc. Further, we also provide stainless steel mill balls, zirconia mill balls, alumina mill balls, PU mill balls, steel carbon mill balls,tungsten mill balls, etc.

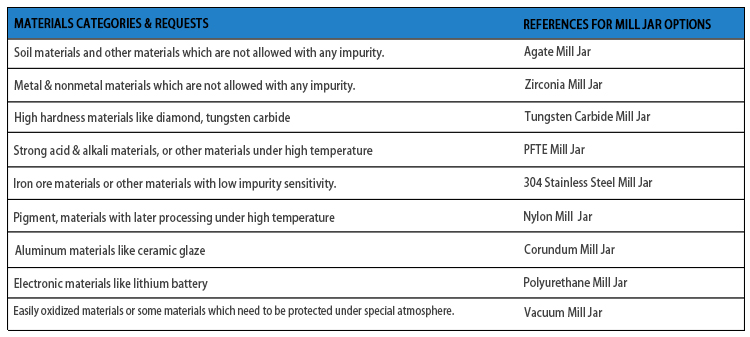

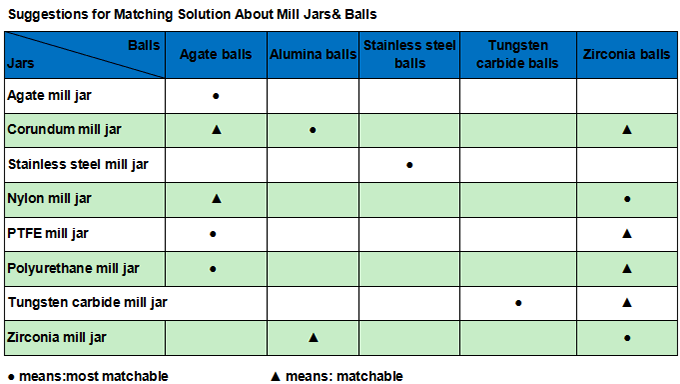

Suggestions for Matching Solution About Mill Jars & Materials

We can also

provide all kinds of mill balls like stainless steel balls, zirconia

balls, alumina balls, PU balls, steel carbon balls, tungsten balls,

agate balls, hard metal balls, silicon nitride balls, high wear

resistant steel ball, manganese steel balls, nylon balls, cemented

carbide, crystal glass and other special metal materials.

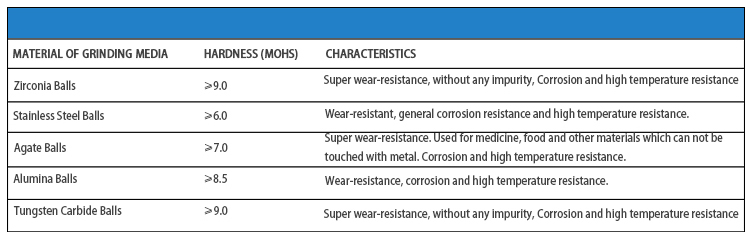

Suggestions for Matching Solution About Grinding Medium & Materials

Pictures of Accessories & Spare Parts

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975