ItemNo :

LITH-YDSMOQ :

1Port :

Xiamen PortCompliance:

CE CertifiedWarranty:

1 Year limited warranty with lifetime supportDelivery Time:

Email :

Louis@lithmachine.comLab Vacuum Electric Heating Laminating Machine of Adjustable Pressure

Lab laminating machine characteristics

1, Thin configuration, complete touch one-click operation, easy to use.

2, Special heating plate, simulate heat compensation, heating surface temperature is more uniform. Heating plate edge special temperature insulation protection strip to ensure that the heat is not lost.

3, Vacuum pump: according to the customer's different use environment: configuration of different vacuum pumps (Germany BUSCH, Leybold, South Korea woo sung, domestic)

4, No leakage point, full coverage chassis heating design, heating more uniform, faster heating.

5, Unique safety limit design, during the switch cover, the hand leaves the touch screen, the machine immediately stops.

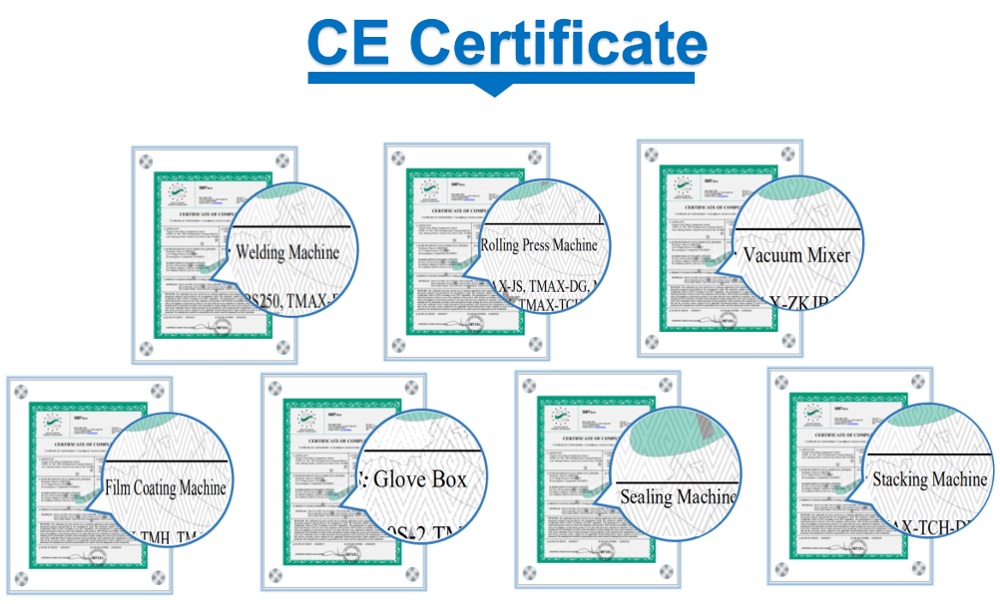

6, CE certification enterprise, import Siemens PLC, Siemens touch screen,

7, Simple engineering mode: can display the number of lamination, can set the operator password, can independently design heating temperature, heating time, lamination pressure

Lab laminating machine specifications and models summary table

|

Model number |

Laminated area (mm) |

Overall dimensions (mm) |

Peak Power consumption (KW) |

Power consumption (KW) |

|

YDS0405 |

400*500 |

1000*800*1080 |

3 |

2 |

|

YDS0509 |

500*900 |

1200*1150*1080 |

6 |

3 |

|

YDS0707 |

700*700 |

1365*980*1080 |

7 |

3 |

|

YDS1010 |

1000*1000 |

1665*1280*1080 |

11 |

5 |

|

YDS1314 |

1300*1400 |

1965*1680*1100 |

16 |

8 |

|

YDS1122 |

1100*2200 |

2460*1820*1245 |

22 |

10 |

|

YDS1525 |

1500*2500 |

2760*2190*1250 |

25 |

12 |

Testing machine parameters (YDS0707 as an example)

|

Equipment type |

YDS0707 |

Lamination area |

700X700mm |

|

Overall dimension |

1365×980×1080mm(height) |

Equipment weight |

0.7T(main engine)+0.2T(vacuum pump) or 38KG |

|

Power source |

380V; Three phases and five lines |

Peak power consumption |

7Kw |

|

Vacuum pump speed |

8L/S |

Operating power consumption |

3Kw |

|

Control mode |

Automatic/manual; Free switching |

Limiting vacuum |

50PA |

|

Heating method |

Electric heating |

Temperature control mode |

PID control |

|

Maximum temperature |

180 ℃ |

Temperature uniformity |

Plus or minus 2 ℃ |

|

Operating temperature |

Room temperature ~180℃ |

Temperature controllable accuracy |

≤±2℃(at the specified temperature setting value) |

|

Table unevenness |

Roughness ≤300μm/m2 |

Bleeder rate |

Continuously adjustable in the range of 0~50L/S |

|

Compressed air pressure |

0.5-0.8 MPA |

Compressed air flow |

5— 10L/S |

|

Vacuum time |

5-7 minutes |

Lamination time |

20 minutes |

|

Operating vacuum |

8 0~20Pa |

Laminate chamber height |

20mm |

|

Cylinder stroke |

400mm |

Adapt to the environment |

0 to 50 ℃ |

Testing machine safety

|

Power failure vacuum vent |

In the case of power failure, the manual lamination can continue, and the air release handle can be moved to complete the air release. |

|

Equipped with gas circuit outage protection |

In the case of sudden power failure, the air circuit system is automatically sealed to prevent the cylinder from falling down the upper cover. |

|

Emergency cover opening system |

In the event of an emergency power failure and other abnormal conditions, you can manually open the upper cover and take out the component. |

|

Set the emergency button |

Emergency situations can be dealt with quickly and forced to cut off the power supply of the whole machine. |

|

Safety can be maintained when the cover is improperly operated |

Set the emergency button switch, press it when there is an accident, the laminating organ will cut off the main power supply, and the upper cover will remain in place. |

|

Insufficient vacuum alarm |

When the vacuum degree of the lower chamber fails to meet the set requirements, the system will alarm. |

|

Insufficient air pressure alarm |

When the compressed air pressure is too low, the system alarms |

Testing machine equipment characteristics

|

Working mode |

Automatic/manual choice of two working modes, automatic operation during normal work, high efficiency, good stability; Adjustment or other situations in a single step manual operation, simple and flexible |

|

The upper cover is designed to prevent the folding of the rubber plate |

Prolong the service life of the rubber plate more than twice, improve the flatness of lamination, reduce the fold of the panel. |

|

Control technology |

It integrates vacuum technology, pneumatic transmission technology, PID self-tuning technology, programmable control technology and relay control technology to realize all digital control of vacuum system, heating system and working process |

|

Control system |

Germany imported Siemens PLC, performance is extremely stable, reliable, high precision, truly in line with industrial automation control standards |

|

Adjustable laminating pressure |

The pressure can be adjusted at will, which can accurately control the laminating pressure and improve the level of three laminating processes. At the same time, high vacuum indicator, timely quantitative monitoring of the vacuum state of the studio, strong anti-interference performance, intuitive and reliable, to ensure the best lamination effect. |

|

Heating platform |

In the state of continuous 24 hours of high temperature operation, the plane of the heating platform is invisible. The unevenness of each square meter in the working area is less than 300μm. Suitable for lamination production of battery components. |

|

Application characteristics |

Can be laminated or cured, equipment production components compatibility; Suitable for general industrial environment and laboratory environment. |

|

Portal type upper cover guard |

When replacing the rubber plate, you only need to open it, without disassembling it. |

|

The rubber plate of the air bag is fixed by flange |

The rubber plate can be replaced quickly |

|

Heating plate and vacuum chamber integrated |

The heating plate works without deformation for a long time, and the vacuum degree of the lower chamber is high |

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975