ItemNo :

LITH-HTDC-600MOQ :

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 daysEmail :

Louis@lithmachine.com

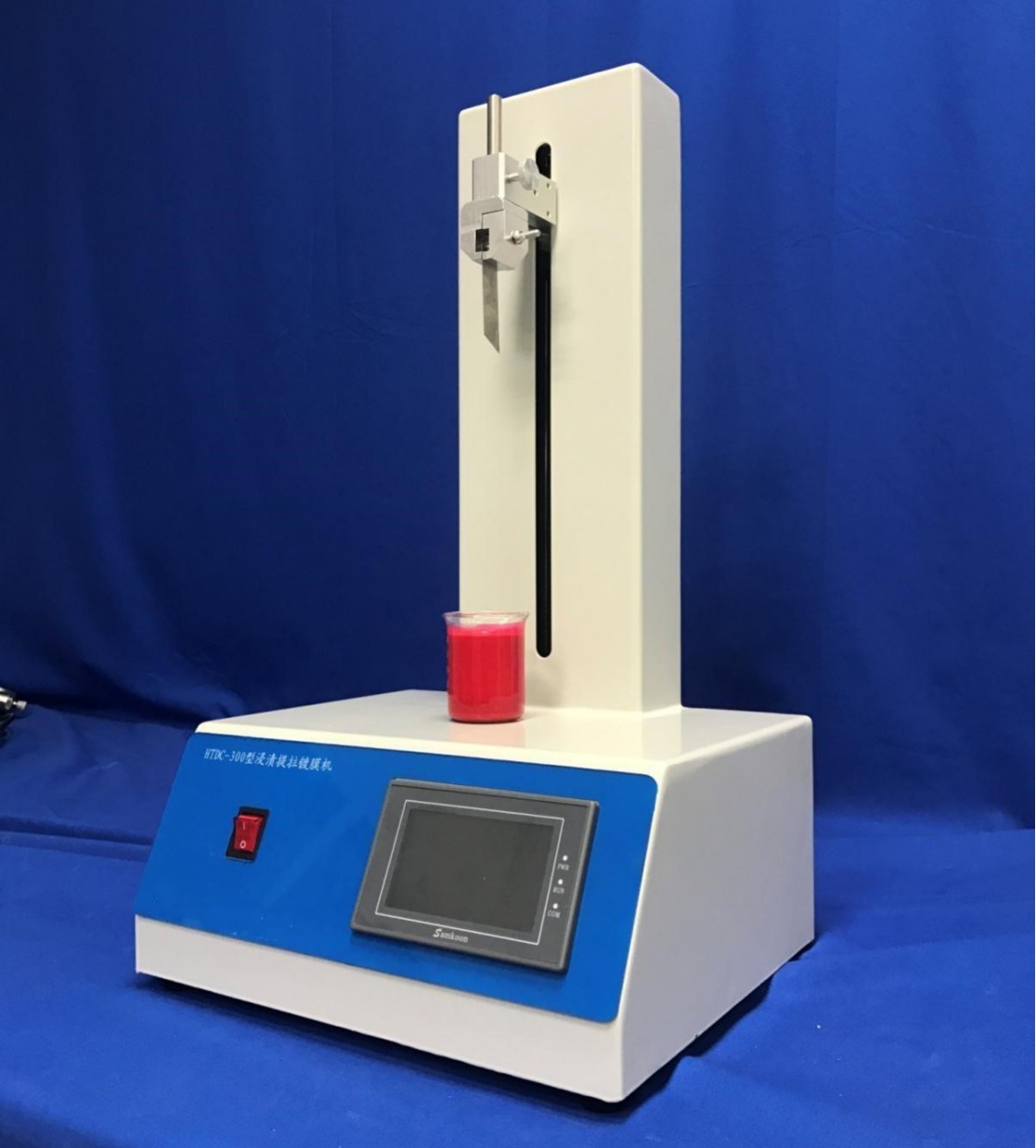

HTDC-600 dip and lift coating machine introduction

HTDC-600 dip and pull coater is a high precision instrument suitable for dipping and pull film preparation by sol-gel method (SOL-GEL method, SG method for short). The core parts adopt imported parts, accurately control the lifting speed, and repeatedly coating without position deviation. Lifting speed, lifting height, impregnation time, number of cycle coatings, impregnation time, descending speed, residence time can be precisely controlled by the program. Applicable to glass, Si (100), Si (111), sapphire (Al₂ O₃), porcelain and resin substrate and other common substrates.

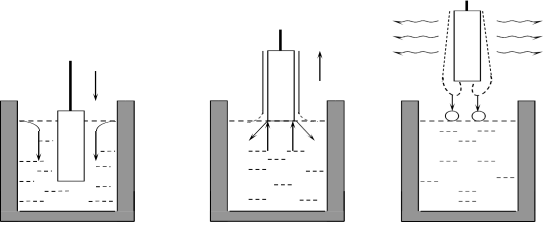

Introduction to dip pulling method

Dip and pull method is to soak the whole cleaned substrate into the pre-prepared sol, and then the substrate is smoothly pulled out of the sol at a precisely controlled uniform speed, and a uniform liquid film is formed on the surface of the substrate under the action of viscosity and gravity, by rapid evaporation of the solvent, so the sol attached to the surface of the substrate quickly gelates to form a layer of gel film. The process diagram is as follows:

There are many factors affecting the thickness of the film, including the viscosity, concentration, specific gravity, lifting speed and pulling Angle of the solution, the viscosity, specific gravity of the solvent, evaporation rate and the temperature and drying conditions of the environment.

HTDC-300 Dip Lift Coating machine Product features:

■ Adopt imported linear guide rail and servo motor to accurately control the uniform lifting speed.

■ Smooth operation without jitter, liquid level without vibration. Ensure the stability of the equipment and the uniformity of film formation.

■ Using the program control system independently developed by Huotong Instrument, lifting speed, lifting height, impregnation time, coating times, coating time, falling speed and falling height can be adjusted by program control

■ High-end brand touch screen, clear interface, easy to operate

■ Special design fixture, clamping more secure and firm

■ The whole machine is sprayed with plastic, the appearance is beautiful and generous.

HTDC-600 Dip and Lift coating machine product parameters:

1. Maximum stroke: 0-600mm

2. Lifting speed range: 1 ~ 9999 μm/s, minimum resolution 1 μm/s

3. Position accuracy: <0.01mm

4. Speed accuracy: ±0.01%

5. Impregnation time: 1 ~ 3600 s

6. Coating times: 1 ~ 1000 times

7. Coating interval: 1 ~ 3600 s

8. Power supply: AC 220V 50Hz

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975