MOQ :

1Delivery Time:

5 daysEmail :

Louis@lithmachine.com

A rotary evaporator is a device used in chemical laboratories for the efficient and gentle removal of solvents from samples by evaporation. The process of rotary evaporation is most often used to separate solvents with low boiling points, such a n-hexane or ethyl acetate, from compounds which are solid at room temperature and pressure. However, careful application also allows for the removal of a solvent from a sample containing a liquid compound, if there is minimal co-evaporation (azeotropic behavior) and a sufficient difference in boiling points at the chosen temperature and reduced pressure.

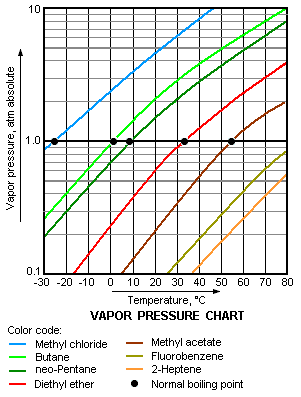

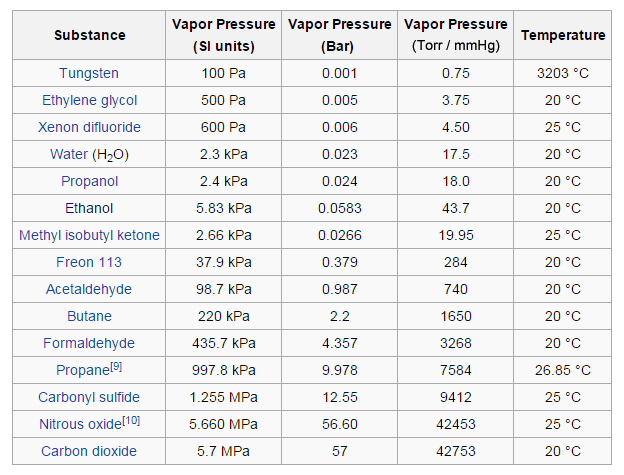

Example: The following table is a list of a variety of substances ordered by increasing vapor pressure (in absolute units).

The

new Ai SolventVap 0.5-gallon/2L (evaporating flask

capacity) series rotary evaporators come with a modular heating

bath, vertical glassware, and digital temperature/rotation control. Its

optimized bath volume allows for rapid heat-up times. The condenser unit has

specially designed glass tubes that utilize surface area extremely efficiently.

That’s why our SolventVap evaporators consistently deliver reliable and

reproducible process results that are usually reserved for more costly systems.

Another important aspect of the SolventVap is the safety features, which

includes dry-run protection, water bath over-temperature shut-off protection,

and fuse protection.

Rotary evaporator features a specially designed motor and

worm gear, which provides constant rotation at speeds from 10 to 180 rpm. As

the flask containing the solvent is rotated, it continually transfers a thin

layer of liquid over the entire inner surface. This gives a very large surface

area for evaporation, which is caused by the gentle heating from the water

bath. The rotating system is fitted with a special seal that allows the

apparatus to be placed under vacuum, effectively reducing the boiling point of

the solvents and removing the vapor phase, making the process much more

efficient. Each unit is also equipped with an easy-to-use vacuum release and a

continuous feed system, which allows solvent to be constantly drawn into the

rotating flask without needing to stop the operation.

Digital water bath operates from ambient temperature to 99°C

(210°F) with PID temperature control stepping at 0.1°C increments. Heating

coils are located directly inside the pan for the most efficient heating

possible. A built-in overheat protector will shut down power, should the

controller fail.

Standard Glassware Set 0.13 gallon (0.5L), 0.26 gallon (1L) or 0.53

gallon (2 liters) pear shaped evaporating flask, 0.26 gallon (1 liter)

round-bottomed receiving flask, and vertical condenser. Rotary evaporators

with vertical glass condenser are great for distillation of solvents with

higher boiling points.

Features

· Solvent-resistant PTFE and Viton gaskets ensuring long time operation.

· Specialized motor with extremely compact, intermeshed worm and worm gear provides precise driving for very quiet, vibration-free operation.

· Downward-condensing vacuum connection design ensures safe vacuum operation.

· Modular design (individual rotary and water bath modules) for easy future upgrades.

· Easy multi-level manual lift with secure lock for the evaporating flask.

· Easy, straight-forward visual operation with digital speed and temperature display.

· PID temperature controller ensures accurate temperature control is maintained.

Your safety is important to us! Please use caution when operating. Users of glass reaction equipment must take all necessary precautions to avoid contact with rotating parts, particularly entanglement of loose clothing, hair, necklaces, or other jewelry. Under these circumstances, the winding action of the rotating parts can draw the user(s) into the apparatus, resulting in breakage of glassware, burns, and/or chemical exposure. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Specifications

|

Electrical requirements |

110V 60Hz single phase, 9.8A, 1075 watts (heater: 1050 watts, rotation motor: 25 watts) |

|

Glass material |

High borosilicate glass 3.3 |

|

Evaporating flask |

Capacity: 0.13 gallon (0.5L), 0.26

gallon (1L) or 0.53 gallon (2L) |

|

Receiving flask |

0.26 gallon (1L) |

|

Condenser |

Glassware: Vertical with dual-spiral

glass tubing |

|

Working environment |

5 to 95°F |

|

Water bath |

Max. temp: 99°C (210°F) |

|

Vacuum |

Connection: 3/8" hose barb x 1

(on condenser) |

|

Safety |

Dry-run, over-temp shut-off, fuse protections |

|

Weight & dimensions |

Rotary evaporator unit/shipping: 21 /

40 Lb |

|

Warranty |

One year warranty on rotary

evaporator except glassware and all sealing gaskets. |

SE05-S1 Standard Package

|

Part description |

Qty |

|

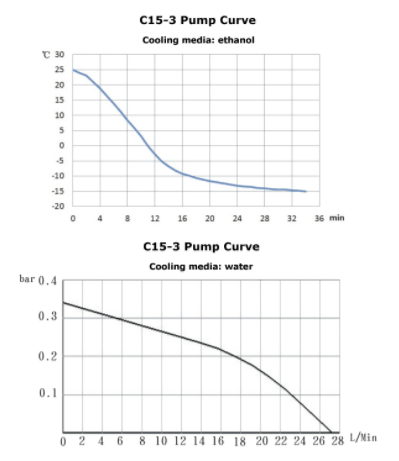

Ai 110V C15-3 -15°C/5°F compact recirculating chiller and accessories |

1 set |

|

Ai 110V WaterVac 0.7 cfm 735 torr 2-head recirculating water pump |

1 pc |

|

Premium food grade silicone vacuum hose |

6 ft |

|

110V evaporator body |

1 pc |

|

110V water bath |

1 pc |

|

Vertical condenser with 2 chilling water ports and 1 vacuum port, glass |

1 pc |

|

2L pear shaped evaporating

flask, glass |

1 pc |

|

0.26G/1L round shaped receiving flask, glass |

1 pc |

|

Glass vapor duct with seal |

1 set |

|

Glass material feeding tube with valve & PTFE extension hose |

1 pc |

|

PTFE vacuum sealing kit |

1 set |

|

Condenser cap kit |

2 pcs |

|

Glass shaft cap and evaporator flask quick-release |

2 pcs |

|

Condenser support and bracket |

1 pc |

|

Condenser support securing screw |

1 pc |

|

Receiving flask ball joint clamp |

1 pc |

|

GL14 connector |

3 pcs |

|

3-prong 110V US power cord for evaporator |

1 pc |

|

Silicone vacuum tubing |

10 ft |

|

Mechanical vacuum gauge |

1 pc |

|

User's manual |

2 pcs |

1. We supply machines with battery technology support.

2. We supply full set of lithium battery equipment for lab research, pilot scale research and production line.

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975