ItemNo :

LITH-VGB-4MOQ :

1Warranty:

2yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.comFour Stations Vacuum Glove Box With Gas Purification System & Filter System

Technical indicators:

|

Water and oxygen content in the tank under standard conditions (Note: The standard condition is one atmosphere, 20 degrees constant temperature) |

≤1ppm |

|

The vacuum value that the transition chamber can withstand |

-0.1MPa |

|

leakage rate |

≤ 0.05vol%/h |

|

Name |

Vacuum Glove Box |

|

Model |

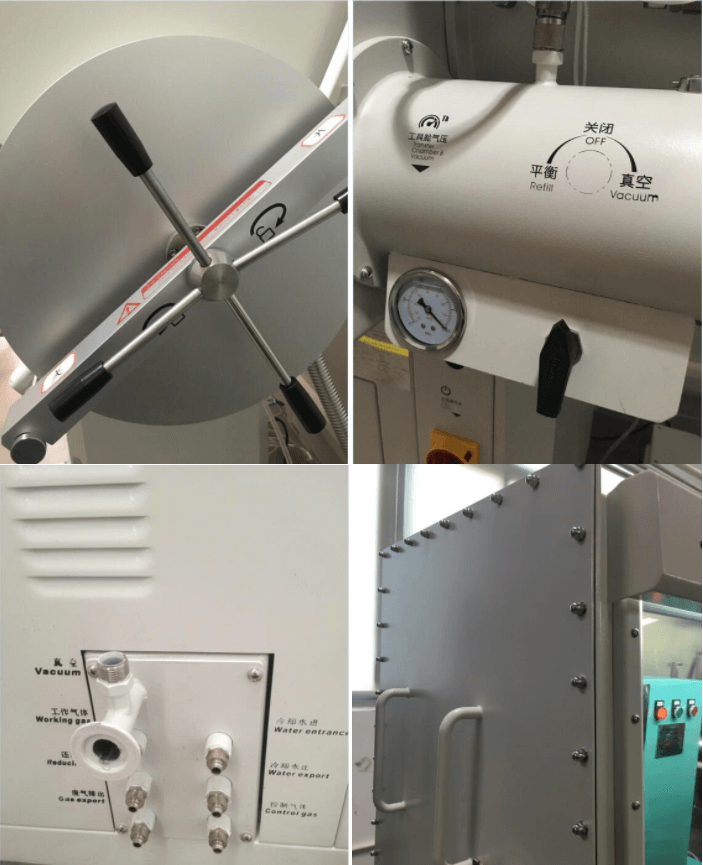

●Box size (operable size): 1900*1000*930mm Overall size (total length of equipment): 2615*1060*1830mm with bracket and moving casters. DN385×600mm (long) SUS304 material, stainless steel with sliding tray. The transition chamber can withstand a vacuum of 100pa. Tool transition chamber: Φ150×300mm (long)

|

|

window |

●Removable safety glass window, inclined design operation surface, tempered glass thickness 12mm

|

|

Gloves port |

●8 (one person with 2 sides for 4 people) |

|

Gloves |

●Thickness: 0.4mm Cuff diameter 200mm, butyl synthetic rubber, brand: US NORTH |

|

Other devices

|

● Four KF40 standard interfaces are reserved, material: SUS304 stainless steel; equipped with quick connector, located on the right side of the box, allowing liquid or gas to enter and exit the box more conveniently ● Double stainless steel shelves are arranged inside the cabinet ● Safety valve, protective equipment and materials in the glove box ● Steel structure bracket, 900mm high, with universal casters installed;

|

|

Air-lock

|

● Large transition chamber: Material: SUS304 stainless steel, thickness 3mm; Dimensions: Φ370X600mm; Position: right side of the box; Connection: welding, no leakage, no sealing aging problem; Transfer method: easy to disassemble by moving the tray, easy to transfer Large volume of material; operation mode: manual operation, touch the valve through the touch screen ● A small transition chamber: Material: SUS304 stainless steel, thickness 3mm. ; Size: Φ150X300mm; Position: right side of the box; connection: welding, no leakage, no sealing aging problem; transmission method: by moving the tray; operation mode: manual operation through the three-way ball valve.

|

|

Gas purification system |

● A gas purification column: (1) selected high-performance copper catalyst and molecular sieve which is most suitable for glove box gas purification, used for water removal and oxygen removal, (2) oxygen and water adsorption capacity of 60 liters and 2 kg, respectively. ● After the gas purification column is saturated with adsorption, it is regenerated with hydrogen-containing nitrogen or argon gas to restore its adsorption capacity, and a hydrogen/nitrogen mixed gas is used as the regeneration gas. H2: 5%; N2: 95%. ● One circulating fan (1) has a flow rate of 90m3/h. (2) It is installed in a sealed stainless steel container, and the stainless steel container is made by all-welding method, and the sealing performance is good. ● Organic solvent adsorption column (1) Contains activated carbon particle adsorption material, and is added with an adsorbent that specifically adsorbs hydrogen fluoride. (2) Replace the new material after the adsorption is saturated. (3) Electric main control circulating main valve, KF40 standard interface. ● All gas paths are controlled by solenoid valves, and the purification column regeneration is fully automatic. The inlet and outlet of the circulation system are equipped with a gas filter.

|

|

Control system |

● The control system consists of Siemens PLC and 7” color touch screen with Chinese and English operation interface. ● The following control functions are realized: (1) Automatic control of tank pressure (a) The user can arbitrarily set the working pressure range between +10 and -10 mbar, and the PLC will automatically regulate the tank pressure within the set range. The default value for the working pressure range is 0 to +5 mbar. (b) When the tank pressure is greater than 12 mbar, the PLC automatically opens the safety valve to relieve pressure and protect the materials in the gloves, equipment and the cabinet. (c) Fine-tune the tank pressure using the foot switch. (2) Manually monitor the leak rate and set the manual test: just press the start detection button, the PLC automatically detects the leak of the box and reports the leak rate of the box. (3) The system historical data is automatically recorded and displayed. The U disk can also be used to export data in a specific time, such as box pressure, water content and oxygen content. (4) Display operation errors and prompts (5) Automatic alarm of the cabinet atmosphere (6) All operations have preset conditions, interlocking actions, avoiding unsafe operation and damaging equipment or damaging the atmosphere inside the cabinet

|

|

Performance index |

● Water content in the tank under standard conditions: ≤1ppm (Note: the standard condition is one atmosphere, 20 degrees constant temperature can reach 0.1ppm) ● Oxygen content in the tank under standard conditions: ≤1ppm (Note: the standard condition is one atmosphere, 20 degrees constant temperature can reach 0.1ppm) ● Leakage rate: ≤0.05Vol%/ h (check the change in oxygen content in the tank) ● Use gas: a) Working gas: N2, Ar, He and other gases b) Control gas: compressed air or inert gas c) reducing gas: a mixture of working gas and hydrogen (H2).

|

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975