ItemNo :

LITH-JLB-10MOQ :

1Compliance:

CE CertifiedWarranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com

Features

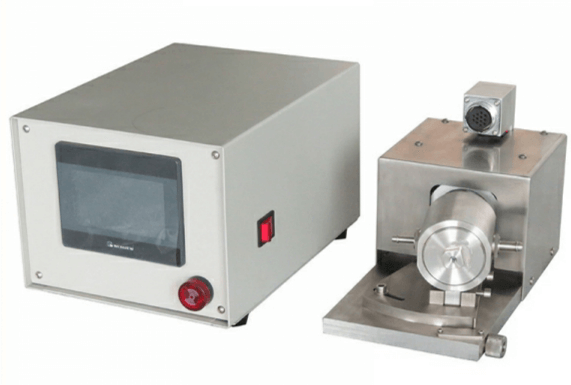

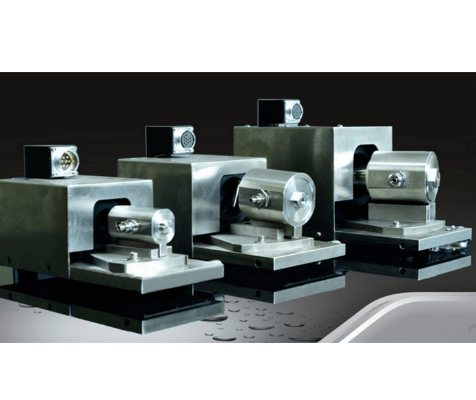

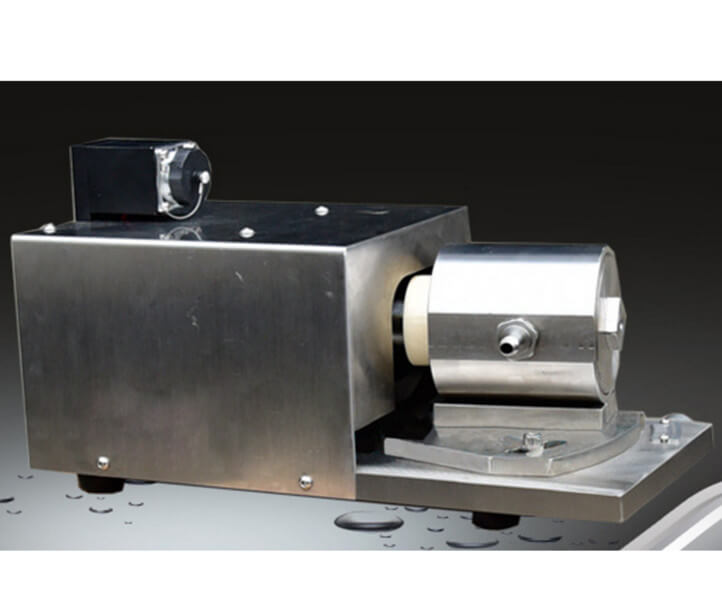

LITH-JLB-10 Electrolyte Filling pump system includes an electronic control box, a stepper motor, and A high-precision rotating fluid reciprocating pump made by special ceramic. It is used for multiple high precision spraying/lithium battery liquid injection system

Technology parameters

|

Model |

Electrolyte Filling Pump System LITH-JLB-10 |

|

Warranty |

Two years limited and lifetime support |

|

Type |

Rotating reciprocating positive displacement special ceramic injection pump |

|

Speed |

1-800 rpm, According to system configuration and fluid characteristics For battery industry, 60-200rpm is best |

|

Stroke number |

1-9999times, According to system configuration and fluid characteristics |

|

Filling range |

0-2.4ml adjustable |

|

Filling accuracy |

Within 3‰ |

|

Source voltage |

AC110-240V, 50/60HZ Single phase |

|

Power |

200W |

|

Dimension (L*W*H) |

Controller box : 340*300*145mm Filling device : 250*200*160mm |

![]()

Cylindrical Cell Process

Power Processing→Power Grinding→Vacuum Mixing→Electrode Coating→Roll Press→Sheet Cutting→Vacuum Drying→Ultrasonic Welding→Electrode Winding→Spot Welding→Grooving→Glove Box→Electrolyte Injection→Electrode Diffusion→Hydraulic Sealing→Battery Analyzer

Related Machine

|

|

|

|

|

|

|

Electrode Slitting |

Welding Power: 80-6500W optional |

Lab cylindrical cell grooving machine |

Manual Sealing or Pneumatic Sealing Machine |

8 Channel Battery Tester

|

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975