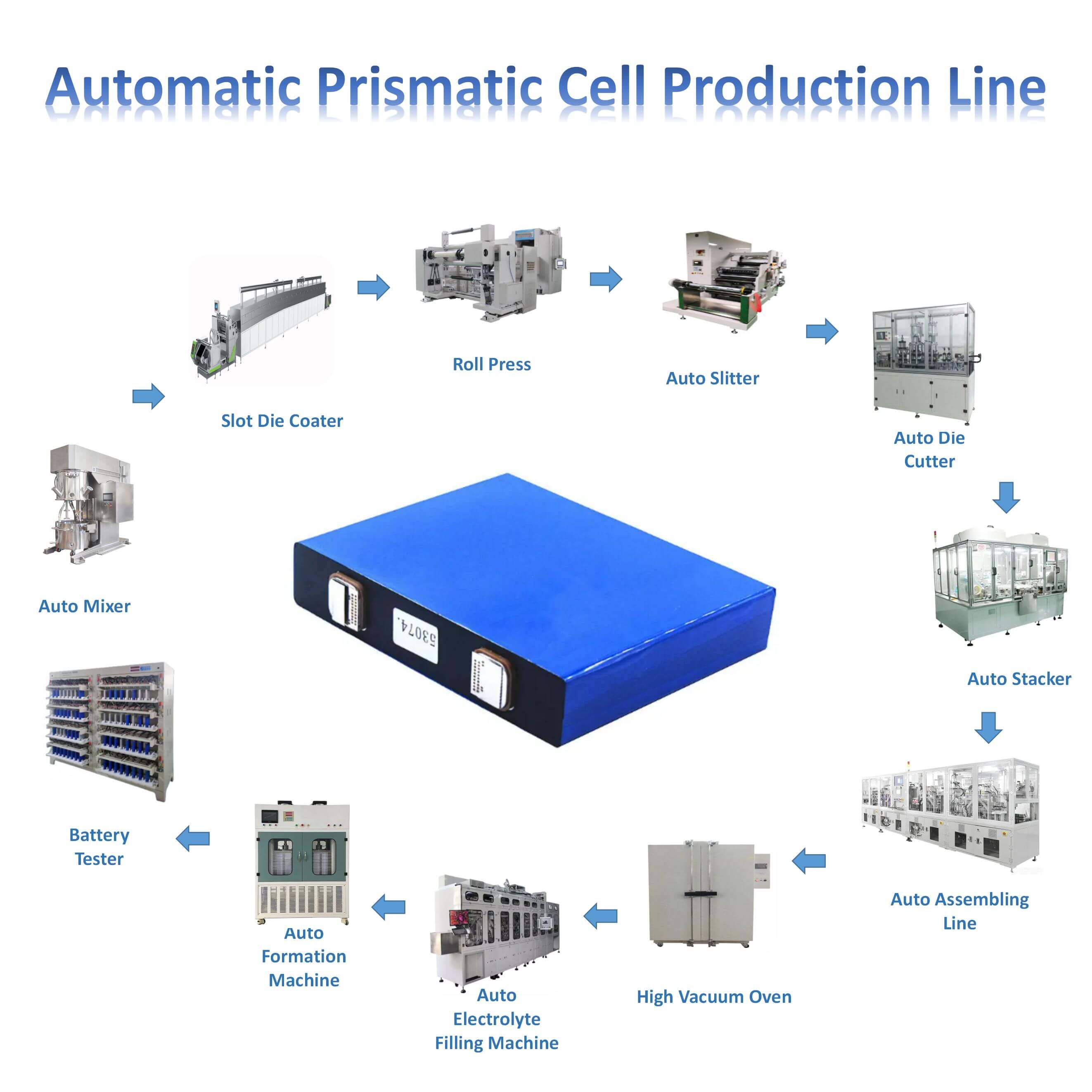

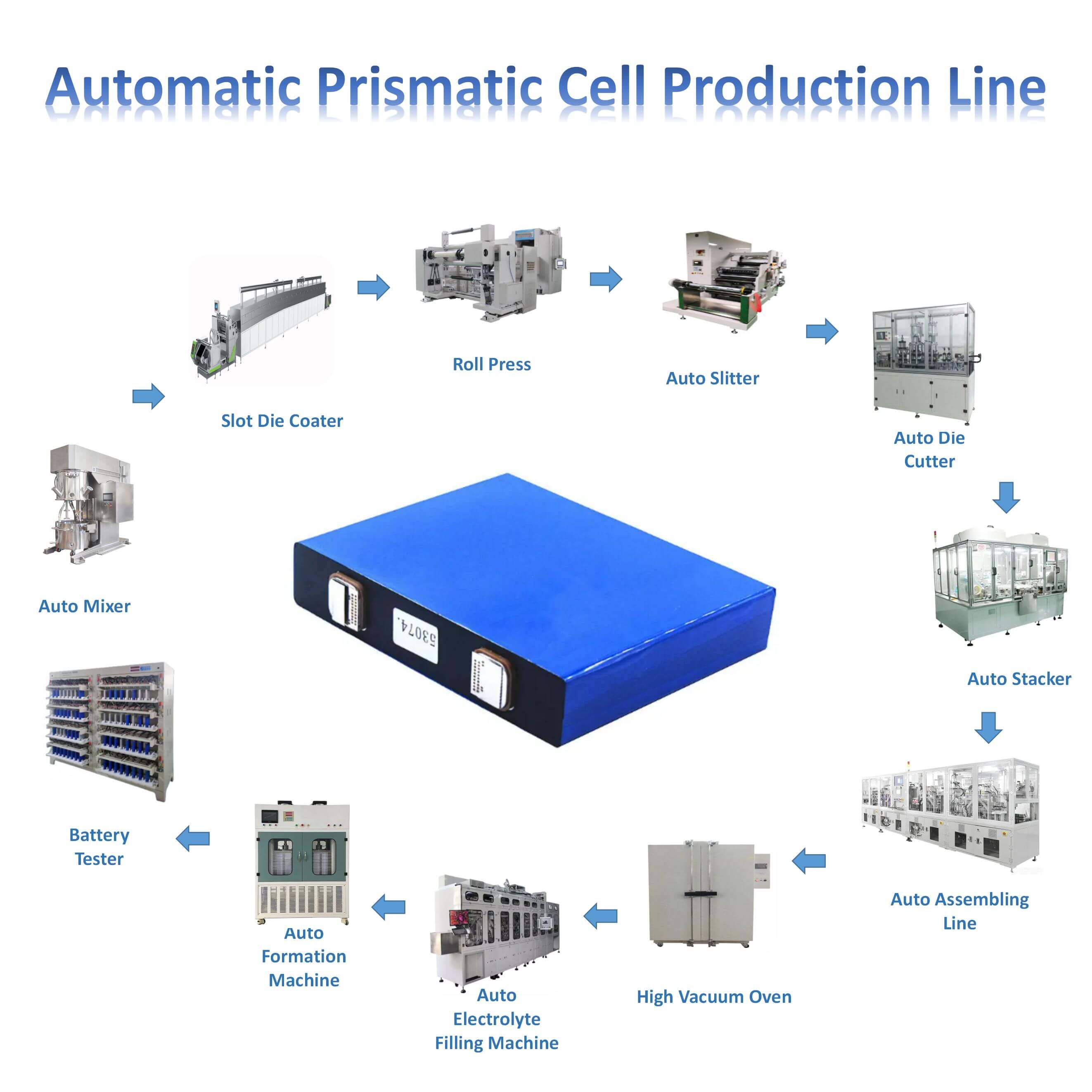

Prismatic battery production equipment typically includes the following devices:

Electrode Coating Machine: Used to apply electrode materials onto current collectors.

Electrode Slitting Machine: Cuts electrode sheets into desired widths for assembly.

Electrode Stacking Machine: Assembles multiple layers of electrodes and separators to create electrode stacks.

Cell Winding Machine: Rolls the electrode stack into a prismatic shape and secures it with tabs.

Cell Sealing Machine: Seals the prismatic cell to ensure it is airtight and leak-proof.

Electrolyte Filling Machine: Injects the electrolyte into the prismatic cell through a filling port.

Formation Equipment: Applies controlled charging and discharging cycles to condition and activate the cells.

Cell Testing Equipment: Performs various tests, such as voltage, capacity, impedance, and safety tests, to ensure cell performance and quality.

Safety precautions during operation include:

Proper Training: Ensure that operators are adequately trained on the equipment and follow standard operating procedures.

Personal Protective Equipment (PPE): Provide and enforce the use of appropriate PPE, such as gloves, goggles, and protective clothing, to prevent injuries.

Equipment Maintenance: Regularly inspect and maintain the production equipment to keep it in safe working condition.

Hazardous Material Handling: Follow proper procedures for handling and storing hazardous materials, including electrolytes and flammable substances.

Emergency Preparedness: Have clear protocols in place for responding to emergencies, including fire, chemical spills, and equipment malfunctions.

Ventilation: Maintain proper ventilation in the production area to prevent the buildup of harmful gases or vapors.

Electrical Safety: Ensure that electrical connections and grounding are in compliance with safety standards to prevent electrical hazards.

Machine Guarding: Install appropriate safety guards and interlocks on machinery to protect operators from moving parts and potential hazards.

By adhering to these safety precautions, prismatic battery production can be conducted in a secure and controlled manner, minimizing risks to personnel and ensuring high-quality output.

Subscribe to us

Subscribe to us ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588