Revolutionizing Energy Storage: The

Prismatic Battery Fabrication Line

Introduction: In recent years, the demand for efficient and reliable energy storage solutions has surged, especially in industries such as electric transportation. Among the various battery technologies, prismatic batteries have emerged as a game-changer, offering exceptional performance and versatility. In this blog post, we will explore the innovative prismatic battery fabrication line, which is revolutionizing the energy storage landscape.

Enhanced Efficiency and Design Flexibility: The prismatic battery fabrication line represents a significant advancement in battery manufacturing. It leverages cutting-edge technology to streamline the production process, resulting in enhanced efficiency and reduced costs. With this fabrication line, battery manufacturers can achieve a higher level of design flexibility, catering to diverse customer requirements across multiple industries.

Superior Energy Density and Longer Lifespan: One of the key advantages of prismatic batteries is their superior energy density. By optimizing the fabrication process, the battery cells can achieve higher energy storage capacities, enabling longer operating times and increased range for electric vehicles. Additionally, prismatic batteries exhibit excellent cycling stability, leading to a longer lifespan and reduced maintenance costs for end-users.

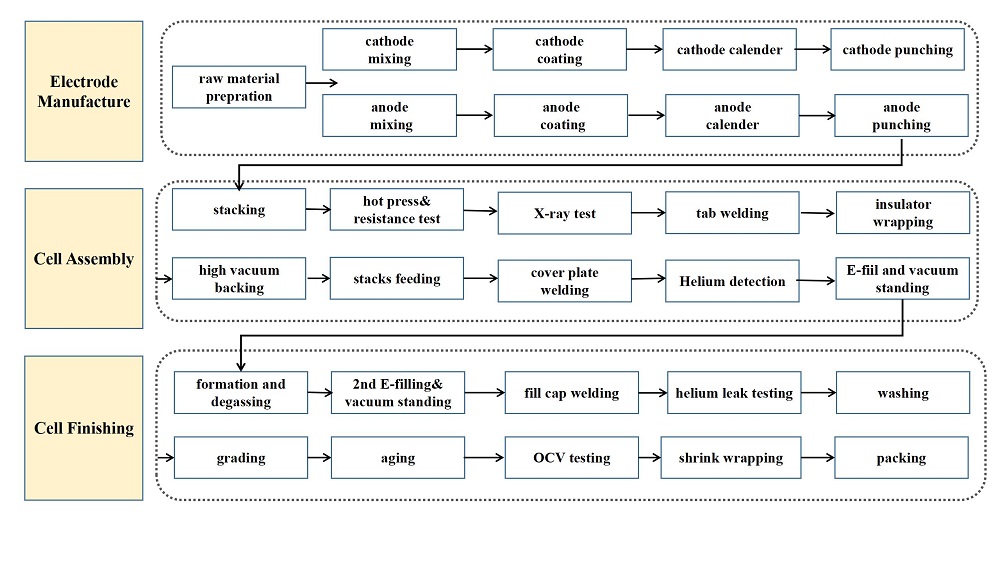

Automation and Precision Engineering: The prismatic battery fabrication line incorporates state-of-the-art automation and precision engineering, ensuring consistent and high-quality battery production. Through automated assembly, cell formation, and packaging processes, manufacturers can minimize human error and achieve greater precision in cell stacking, electrolyte filling, and electrode coating. This level of precision ensures reliable and robust battery performance.

Scalability and Production Capacity: The scalability of the prismatic battery fabrication line is a significant advantage. Manufacturers can easily adjust production volumes to meet fluctuating market demands. Whether catering to small-scale energy storage systems or large-scale electric vehicle fleets, the fabrication line allows for seamless scalability, ensuring efficient utilization of resources and meeting the requirements of diverse applications.

Quality Assurance and Safety Standards: In the prismatic battery fabrication line, quality assurance is of utmost importance. Stringent testing protocols are implemented at each stage of the manufacturing process to ensure the highest quality standards are met. Additionally, safety measures are integrated into the fabrication line design, safeguarding against potential risks associated with battery production, storage, and transportation.

Advancing Sustainable Energy Solutions: The prismatic battery fabrication line plays a vital role in advancing sustainable energy solutions. Prismatic batteries are not only more energy-efficient but can also be recycled at the end of their life cycle. By investing in the fabrication line, manufacturers contribute to a circular economy, minimizing waste and reducing reliance on non-renewable energy sources.

Conclusion: The prismatic battery fabrication line represents a significant milestone in energy storage technology. Through enhanced efficiency, design flexibility, and superior performance, prismatic batteries are empowering the electric transportation sector and driving the transition towards a greener future. As the demand for sustainable energy solutions continues to rise, the prismatic battery fabrication line is poised to play a pivotal role in meeting the energy storage needs of tomorrow.

Equipment List:

|

S NO.

|

Equipment

|

|

1

|

Cathode Mixer

|

|

2

|

Anode Mixer

|

|

3

|

Cathode Slot Die Coater

|

|

4

|

Anode Slot Die Coater

|

|

5

|

NMP Recovery System

|

|

6

|

Cathode Calender

|

|

7

|

Anode Calender

|

|

8

|

Cathode Slitting Machine

|

|

9

|

Anode Slitting Machine

|

|

10

|

Cathode Die Cutting Machine

|

|

11

|

Anode Die Cutting Machine

|

|

12

|

Auto Stacking Machine

|

|

13

|

Hot Press Machine

|

|

14

|

Ultrasonic Battery Core Pre Welding Machine

|

|

15

|

Ultrasonic Battery Core Welding Machine

|

|

16

|

Cover Plate Welding Machine

|

|

17

|

Battery Core Film Covering Machine

|

|

18

|

Integrated Machine for

Shell Welding

|

|

19

|

Primary Helium Testing Machine

|

|

20

|

High Level Vacuum Oven

|

|

21

|

Electrolyte Filling Machine

|

|

22

|

Negative Pressure Forming Machine

|

|

23

|

Sealing &laser Welding Machine

|

|

24

|

Grading Machine

|

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975