The establishment of a

Prismatic Battery Manufacturing Line requires a comprehensive approach to facility design, equipment selection, process optimization, and quality control. This manufacturing line is responsible for producing prismatic batteries, which are widely used in various applications such as electric vehicles, energy storage systems, and portable electronics. In this response, I will outline the key aspects involved in setting up a Prismatic Battery Manufacturing Line.

Facility Design:

The facility should be designed to accommodate the specific requirements of prismatic battery manufacturing. Consider the following aspects:

Sufficient space: Allocate adequate space for different manufacturing processes, equipment, storage, and material handling.

Safety considerations: Implement proper safety measures, including ventilation systems, fire suppression systems, emergency exits, and designated areas for hazardous material storage.

Controlled environment: Maintain controlled temperature and humidity levels throughout the facility to ensure optimal battery production conditions.

Cleanroom facilities: Depending on the specific battery requirements, incorporate cleanroom areas to minimize contaminants during cell assembly.

Equipment Selection:

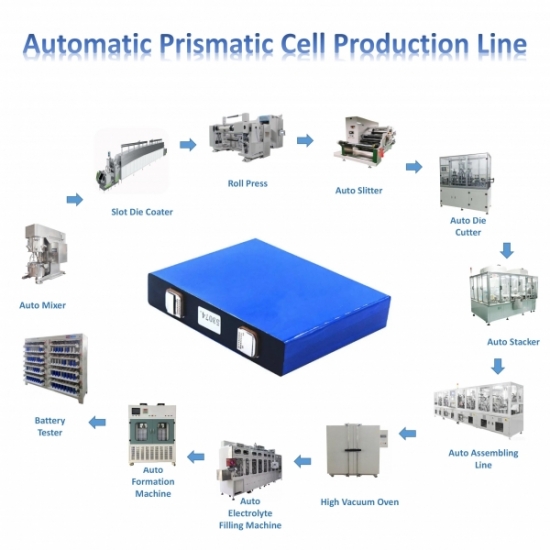

Carefully select the appropriate equipment to support the various stages of prismatic battery manufacturing. This may include:

Electrode preparation: Utilize coating machines, drying ovens,

electrode slitting machine, and

electrode cutting machines to produce uniform electrode materials with precise dimensions.

Assembly: Employ winding machines, tab welding machines, and stacking machines to assemble the electrode layers, separators, and current collectors into a jelly roll structure.

Cell formation: Implement cell formation equipment such as electrolyte filling machines and cell pressing machines to ensure proper electrolyte filling and compression of the cell components.

Formation and aging: Utilize formation and aging chambers to condition the batteries and optimize their performance and stability.

Testing and quality control: Invest in battery testing equipment, including battery cyclers, impedance analyzers, and capacity testers, to evaluate the performance, capacity, and safety of the batteries.

Process Optimization:

Efficient and optimized manufacturing processes are crucial for consistent and high-quality battery production. Consider the following factors:

Process flow: Design a streamlined flow of operations, ensuring a logical sequence of manufacturing steps to maximize efficiency and minimize production bottlenecks.

Automation and robotics: Incorporate automation and robotics where applicable to improve productivity, reduce manual labor, and enhance process control.

Quality assurance: Implement strict quality control measures at each stage of production to identify and eliminate defects, ensuring the reliability and safety of the batteries.

Continuous improvement: Establish procedures for continuous process monitoring, data analysis, and feedback loops to identify areas for optimization and drive ongoing improvements.

Assemble a skilled and knowledgeable workforce to operate and manage the Prismatic Battery Manufacturing Line. This may include:

Battery engineers: Employ professionals with expertise in battery technology, cell design, and manufacturing processes to oversee production and quality control.

Technicians: Hire experienced technicians who can operate and maintain the manufacturing equipment, perform routine maintenance, and troubleshoot any issues that may arise.

Quality control personnel: Appoint dedicated quality control personnel responsible for ensuring adherence to quality standards, conducting inspections, and performing data analysis.

Training programs and continuous professional development opportunities can further enhance the skills and knowledge of the workforce.

In summary, establishing a Prismatic Battery Manufacturing Line requires careful consideration of facility design, equipment selection, process optimization, and skilled personnel. By creating a well-designed facility, choosing the right equipment, optimizing manufacturing processes, and assembling a competent workforce, it is possible to achieve efficient and reliable production of high-quality prismatic batteries.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975