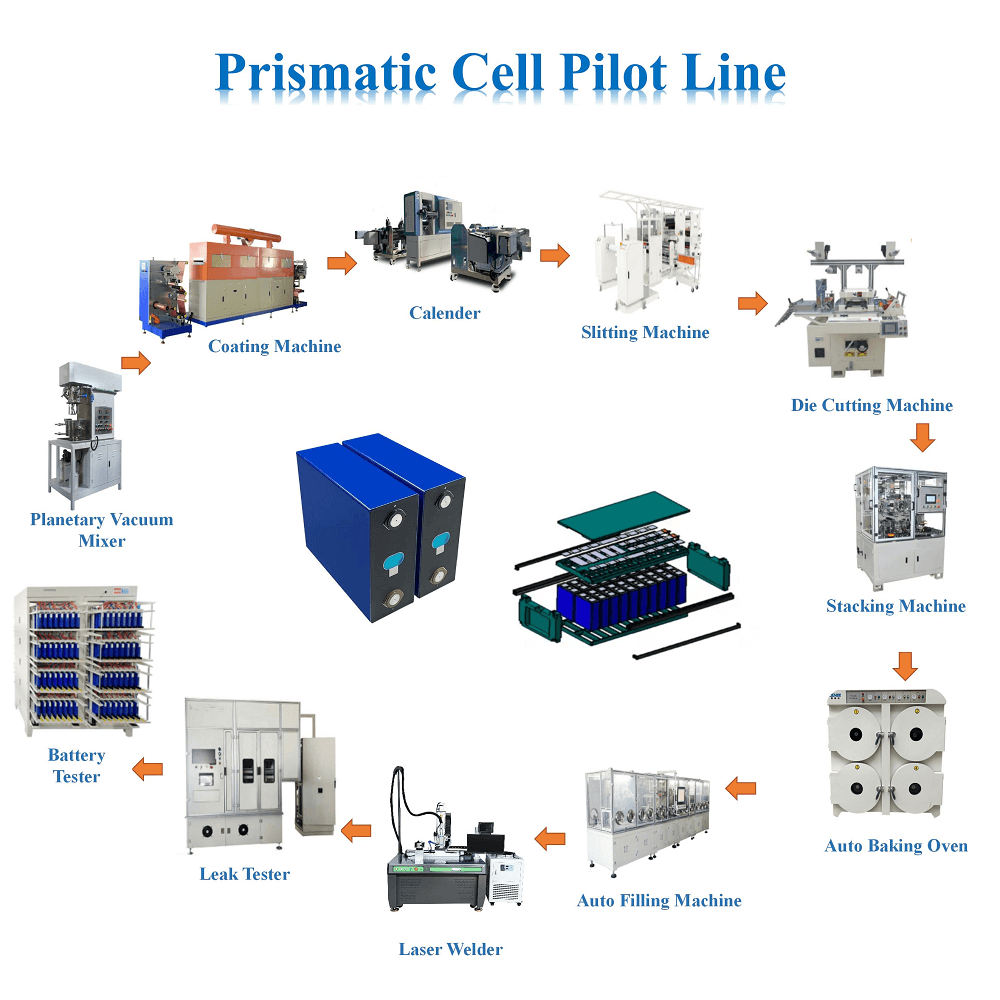

Electrode manufacturing: mixing, coating, calendering, and cutting the positive and negative materials to make electrode sheets.

Cell assembly: Laminate or wind the positive and negative electrodes and diaphragm to form a cell, and perform processes such as liquid injection and packaging.

Module assembly: multiple batteries are connected in series or in parallel through connectors to form a module, and thermal management systems such as water cooling plates and thermal pads are installed.

Ev battery pack assembly line: Connect multiple modules through high and low voltage wiring harnesses to form a PACK, and install battery management systems, flame retardant and heat insulation protection layers, etc.

Testing and testing: Quality testing of products in each production link, including air tightness, insulation, air tightness, OCV, etc., and charge and discharge tests on PACK.The mechanical equipment involved include: battery charge tester,battery capacity tester,Battery impact Tester,battery drop tester,battery climate Test Chamber,battery projectile test chamber, Altitude Simulation pressure Tester,Acceleration Mechanical Shock Test Machine , etc.

The design and implementation of an automotive battery production line needs to consider a variety of factors, such as production efficiency, space utilization, degree of automation, data collection and analysis, traceability, etc.

No. 5 Nanshan Road, Huli District, Xiamen City, Fujian Province, China

Subscribe to us

Subscribe to us ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975