Pouch cell laboratory machine is critical for research, development, and testing in the field of pouch cell technology, a type of lithium-ion battery. This equipment facilitates the production and analysis of pouch cells at a smaller scale for research purposes. Here are some essential pouch cell lab equipment:

Coating Machine:

Doctor Blade Coater: This machine is used to coat a uniform layer of electrode slurry onto a current collector, typically a metal foil. It ensures a consistent application of the electrode material.

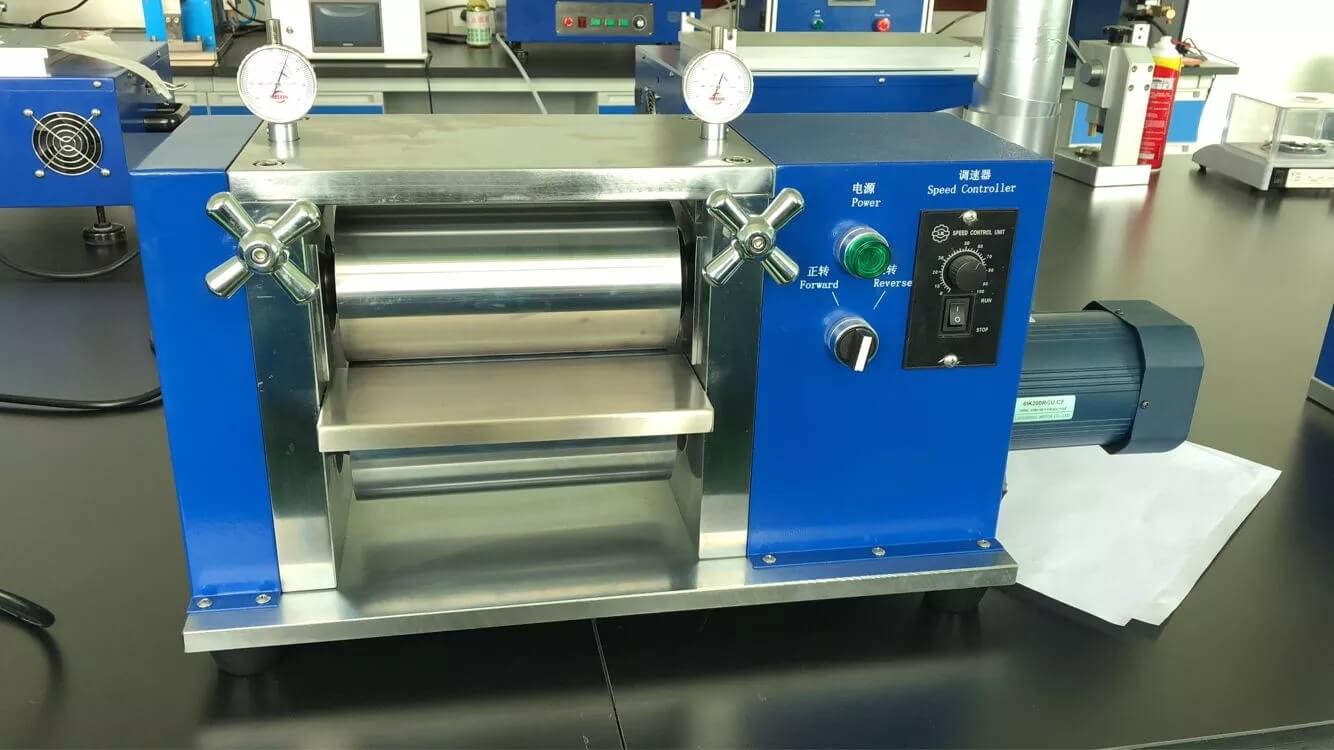

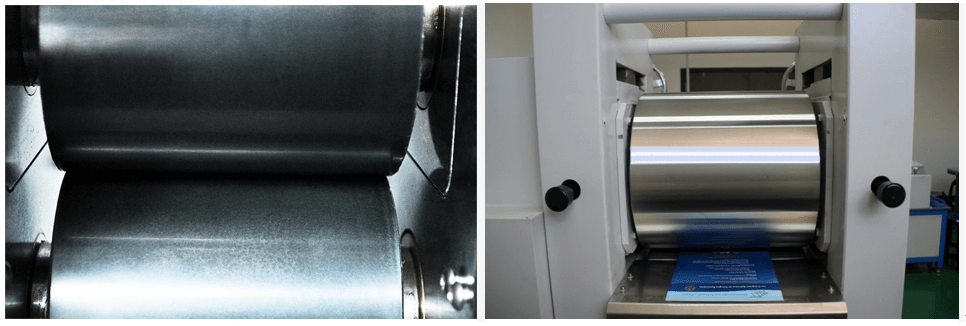

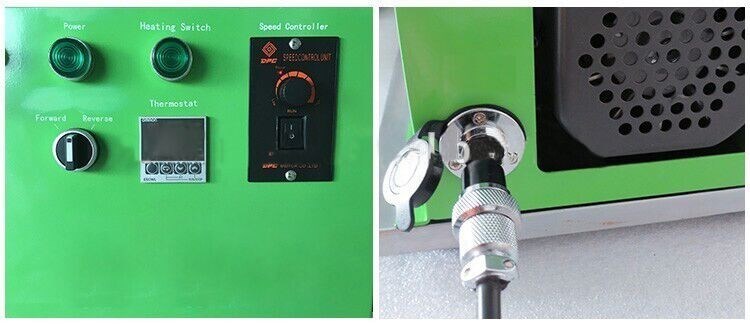

Calender Machine:

Rolling electrode Calender The rolling calender is employed to compress the coated electrode layers, adjusting the thickness and improving the overall quality of the electrodes.

Slitting Machine:

Electrode Slitter: This machine is responsible for cutting the coated electrode sheets into strips of the required width for the assembly of pouch cells.

Electrode Stacking Equipment:

Manual or Semi-Automatic Stacker: For laboratory-scale production, electrode stacking may be done manually or with a semi-automatic stacking machine. It allows for precise control over the stacking process.

Winding Machine:

Manual Winder: In smaller-scale settings, a manual winder is used to create a jelly roll structure by winding electrode layers and separator materials together.

Pouch Forming Machine:

Manual Pouch Forming Tool: Laboratories may use manual pouch forming tools that simulate the sealing process on a smaller scale. These tools help shape the pouch cells.

Electrolyte Filling Equipment:

Syringe or Pipette: Researchers use manual methods like syringes or pipettes to carefully fill pouch cells with electrolyte, ensuring precision in the process.

Sealing Equipment:

Heat Sealer or Manual Sealing Tool: Heat sealers or manual sealing tools are employed to seal the pouch cells after filling with electrolyte. This step is crucial for ensuring the integrity of the pouch cell.

Formation and Testing Chambers:

Small-Scale Formation Chamber: Laboratories may have smaller-scale chambers dedicated to the formation of pouch cells. This allows researchers to study the initial charge-discharge cycles.

Testing and Analysis Equipment:

Impedance Analyzer, Voltage Tester, Cycler: Various testing equipment is used for analyzing the performance of pouch cells, including impedance analyzers, voltage testers, and cyclers for cycling tests.

Safety Testing Equipment:

Thermal Chamber, Safety Tester: Safety testing equipment is crucial for assessing the safety characteristics of pouch cells, including thermal chambers for evaluating thermal stability.

Microscopy and Imaging Tools:

Microscopes, Imaging Systems: Microscopes and imaging systems help researchers examine the microstructure and morphology of pouch cell components.

Environmental Control Systems:

Glove Boxes, Environmental Chambers: These systems create controlled environments for handling and testing pouch cells in inert atmospheres.

Data Acquisition Systems:

Data Loggers: Systems for collecting and analyzing data during experiments to monitor the behavior and performance of pouch cells.

These pouch cell lab equipment components collectively support the research, development, and testing of pouch cells in laboratory settings. They enable scientists and engineers to explore and optimize pouch cell technology for various applications.

No. 5 Nanshan Road, Huli District, Xiamen City, Fujian Province, China

Subscribe to us

Subscribe to us ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975