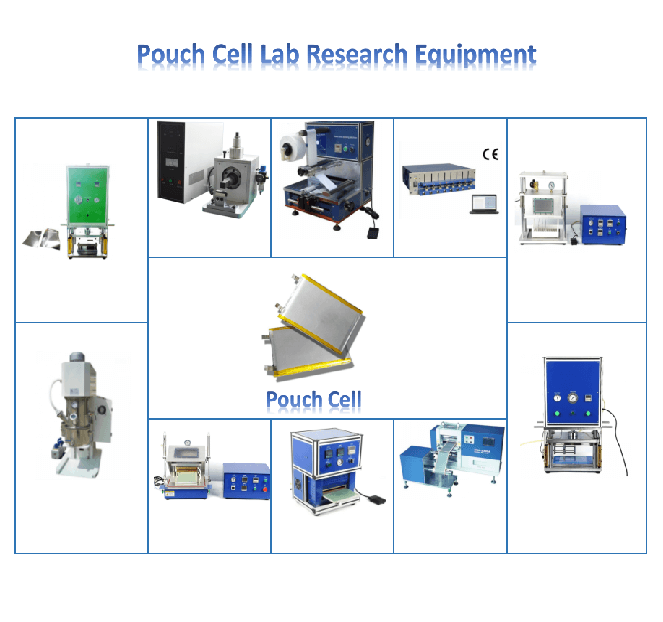

Pouch cell fabrication line refers to the machinery and tools used in the manufacturing process of pouch cells, a type of rechargeable lithium-ion battery. Pouch cells are characterized by their flexible, flat, and lightweight design, making them suitable for various applications, including electric vehicles, consumer electronics, and renewable energy storage. The fabrication equipment is essential for producing high-quality pouch cells with precise specifications. Here are key components of pouch cell fabrication equipment:

Coating Equipment:

Coating Machine: A precision coating machine is used to apply electrode materials, such as cathode and anode materials, onto metal foils. This ensures uniform and controlled thickness of the electrode layers.

Calendering Machine:

Electrode Calender Machine: This equipment compresses the electrode layers to the required thickness, enhancing their density and improving overall performance.

Slitting Machine:

Electrode Slitting Machine: The slitting machine cuts the coated electrode sheets into narrower strips, optimizing them for specific cell dimensions.

Electrode Stacking Equipment:

Stacking Machine: Pouch cells consist of stacked layers of electrodes and separators. Stacking machines automate the precise alignment and arrangement of these layers to form the cell's structure.

Winding Machine:

Winding Machine: In some designs, especially for large-format pouch cells, a winding machine is used to create a jelly roll structure by winding electrode layers and separator together.

Forming Machine: Pouch forming machines shape and seal the cell's flexible pouch. They heat-seal the edges to encapsulate the electrode stack, electrolyte, and separator within the pouch.

Electrolyte Filling Equipment:

Filling Station: This equipment fills the pouch cell with the required electrolyte solution in a controlled and precise manner.

Sealing Equipment:

Sealing Machine: After filling, the pouch is sealed to prevent leakage and ensure the integrity of the cell. Sealing machines use heat or other sealing methods.

Formation and Aging Chambers:

Formation Chamber: Pouch cells undergo a formation process to stabilize their performance. Formation chambers control temperature and other environmental factors during this crucial phase.

Testing and Quality Control Equipment:

Testing Stations: Various testing equipment, such as impedance analyzers, voltage testers, and thermal chambers, are used for quality control and performance testing.

Safety Testing Equipment:

Safety Testing Chamber: Pouch cells undergo safety testing to ensure they meet industry standards. Safety testing equipment includes tools for thermal, electrical, and mechanical testing.

The integration of these pouch cell fabrication equipment components ensures the efficient and reliable production of high-performance pouch cells for diverse applications in the rapidly evolving field of battery technology.

No. 5 Nanshan Road, Huli District, Xiamen City, Fujian Province, China

Subscribe to us

Subscribe to us ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975