Lithium Battery Fabrication equipment : Technical Overview

Lithium-ion batteries have become an essential component in various applications, including electric vehicles, portable electronic devices, and renewable energy systems. To meet the increasing demand for lithium-ion batteries, advanced manufacturing technologies have been developed. Among these technologies, the lithium battery fabrication machine has emerged as a crucial piece of equipment for efficient and reliable battery production.

The lithium battery fabrication machine is a highly automated system that performs various tasks, including electrode manufacturing, cell assembly, and battery pack assembly line. The machine consists of multiple modules that can be configured based on the desired battery specifications. Here is a technical overview of some of the key modules of a lithium battery fabrication machine:

Electrode coating machine : This module is responsible for applying the electrode active material onto the current collector. It uses various coating techniques such as doctor blade, slot-die, or gravure coating.

Electrode drying module: This module is used to dry the coated electrode before the next step. The drying process is critical to ensure the uniformity of the electrode.

Electrode calendering module: This module is responsible for compressing the coated electrode to improve its mechanical and electrochemical properties. It uses rollers to achieve the desired thickness and density.

Slitting module: This module is used to cut the electrode into the desired width to match the cell size.

Cell winding module: This module is responsible for winding the electrodes with the separator to form a jelly-roll. It can handle different electrode widths, separator materials, and winding tensions.

Cell assembly module: This module is used to insert the jelly-roll into the cell casing, add electrolyte, and seal the cell. It requires precise control of the electrolyte volume, filling temperature, and sealing pressure.

Formation module: This module is responsible for activating the cell by cycling it through multiple charge and discharge cycles. It also includes safety features to detect any abnormalities during the process.

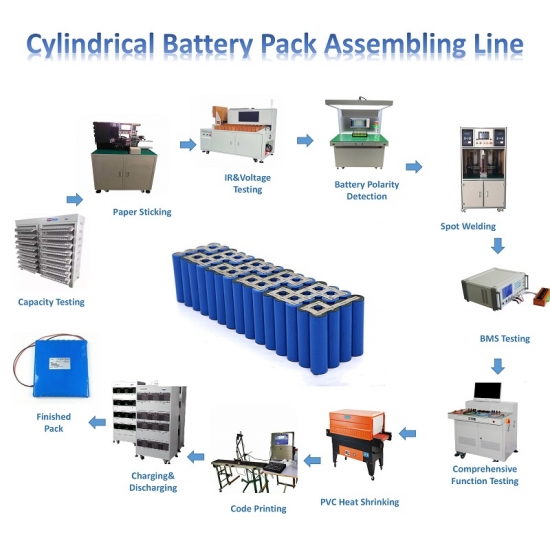

Pack assembly module: This module is used to combine multiple cells into a battery pack. It includes cell interconnects, thermal management, and safety features such as fuses and circuit breakers.

Overall, the lithium battery fabrication line is a complex system that requires expertise in multiple fields such as mechanical engineering, electrical engineering, chemistry, and automation. The advancements in lithium battery fabrication technology have enabled the production of high-performance batteries with improved safety, energy density, and lifespan. With the increasing demand for lithium-ion batteries, the lithium battery fabrication machine will continue to play a critical role in the industry's growth.

No. 5 Nanshan Road, Huli District, Xiamen City, Fujian Province, China

Subscribe to us

Subscribe to us ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975