Lithium Battery Assembly equipment: Streamlining Your Battery Production Process

As the demand for lithium batteries continues to grow, manufacturers are constantly seeking ways to optimize their production processes to increase efficiency, reduce waste, and lower costs. This is where the lithium battery assembly machine comes in.

A lithium battery assembly machine is a highly specialized piece of equipment designed to automate and streamline the battery production process. It is capable of handling a wide variety of battery types and sizes, making it an ideal solution for manufacturers looking to improve their production throughput.

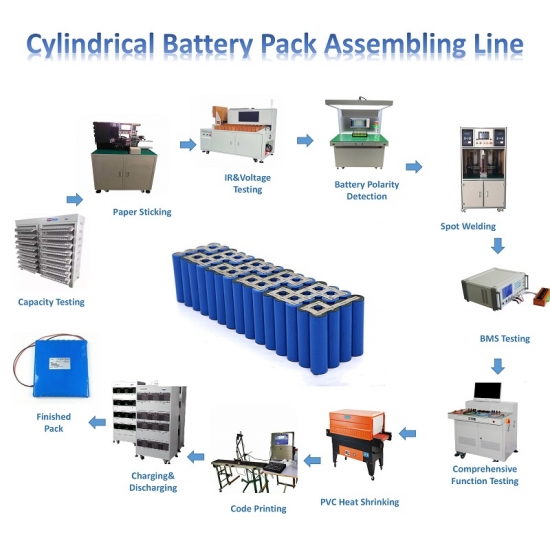

At its core, the lithium battery assembly line consists of several key components. These include:

1. Battery module positioning system - This system is responsible for accurately positioning battery modules for the assembly process, ensuring that each module is in the correct position for the next step in the process.

2. Electrode stacking machine - This system is used to stack the electrode layers and create the battery cells. It is a critical component in the assembly process, as the accuracy and precision of the electrode stacking process can have a significant impact on the battery's overall performance.

3. Cell welding system - This system is used to weld the cells together, creating a complete battery pack. It is designed to ensure that the cells are securely welded, without causing any damage to the cells themselves.

4. Cell sorting and grading system - This system is used to sort and grade the cells based on their capacity and other key parameters. This allows manufacturers to create battery packs that are highly uniform and consistent in performance.

5. Battery pack testing machine - This system is used to test the battery pack's performance and ensure that it meets the required specifications. It can detect any defects or issues with the battery pack before it is shipped to the customer.

6. Battery pack labeling system - This system is used to label the battery packs with the required information, such as the voltage, capacity, and other relevant details.

7. Battery pack packaging system - This system is used to package the battery packs, ensuring that they are protected during shipping and storage.

8. Software control system - This system is responsible for controlling and coordinating the various components of the assembly machine, ensuring that the process is optimized for maximum efficiency and quality.

By using a lithium battery assembly machine, manufacturers can significantly reduce the time and labor required for battery production, while also improving the overall quality and consistency of the batteries they produce. This can translate into significant cost savings and improved customer satisfaction.

If you are a lithium battery manufacturer looking to optimize your production process and stay ahead of the competition, investing in a lithium battery assembly machine is a smart decision. With the right machine and the right processes in place, you can take your battery production to the next level and achieve new levels of success.

No. 5 Nanshan Road, Huli District, Xiamen City, Fujian Province, China

Subscribe to us

Subscribe to us ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975