Electric vehicle battery assembly plant refers to the process of building a battery pack that can power an electric vehicle. This process involves several steps, including the production of individual battery cells, the assembly of these cells into modules, and the integration of these modules into a complete battery pack.

The first step in EV battery assembly line is the production of battery cells. These cells are typically made using lithium-ion technology, which provides a high energy density and a long lifespan. The cells are manufactured in a highly controlled environment to ensure their quality and consistency.

Once the cells are produced, they are assembled into modules. These modules typically contain several cells and are designed to provide a specific voltage and capacity. The modules are often enclosed in a protective casing to ensure their safety and to facilitate their integration into a larger battery pack.

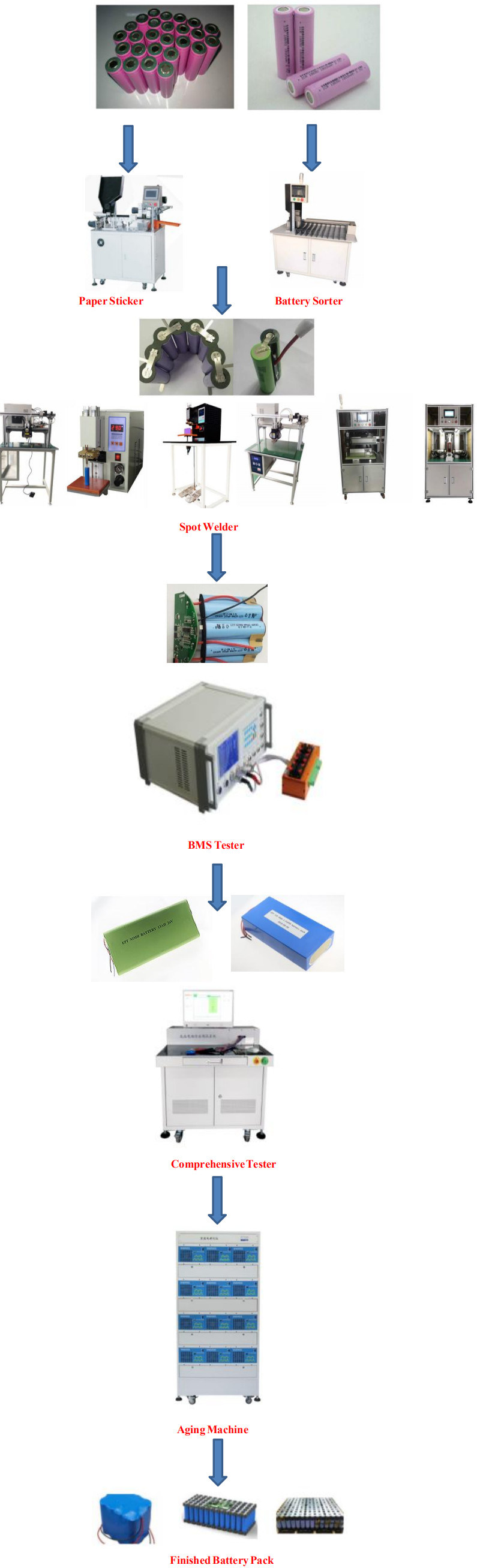

The final step in EV battery assembly machine is the integration of the modules into a complete battery pack. This process involves connecting the modules in series and parallel configurations to achieve the desired voltage and capacity. The battery pack is also equipped with a battery management system (BMS TESTER), which monitors the state of the cells and ensures their safe operation.

Overall, EV battery assembly is a complex process that requires careful attention to detail and a focus on quality and safety. As demand for electric vehicles continues to grow, this process will become increasingly important in ensuring the widespread adoption of electric transportation.

EV battery assembly involves several pieces of equipment, including:

Battery Cell Manufacturing Equipment: This equipment includes machines that can produce the individual battery cells, such as electrode coating machine, calendering machines, and cell assembly machines.

Module Assembly Equipment: This equipment is used to assemble the battery cells into modules. It can include stacking machines, welding machines, and module testing machines.

Battery Pack Assembly Equipment: This equipment is used to integrate the battery modules into a complete battery pack. It can include pack assembly machines, cell interconnect machines, and pack testing machines.

Battery Testing Equipment: This equipment is used to test the performance and safety of the battery pack. It can include thermal chambers, battery cyclers, and testing software.

Battery Management System (BMS): This is a critical component of the EV battery assembly process. The BMS is responsible for monitoring and controlling the battery cells to ensure their safe and efficient operation. It typically includes sensors, controllers, and software.

In addition to the above equipment, EV battery assembly may also require tools such as torque wrenches, battery cell cutters, and battery crimpers. The specific equipment and tools required for EV battery assembly will depend on the type of battery technology being used, the size of the battery pack, and other factors.

No. 5 Nanshan Road, Huli District, Xiamen City, Fujian Province, China

Subscribe to us

Subscribe to us ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975