ItemNo :

LITH-TMHMOQ :

1Delivery Time:

5 daysEmail :

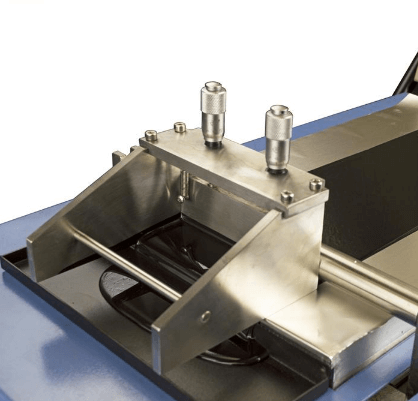

Louis@lithmachine.comLITH-TMH is a compact tape casting coater with a heating cover designed to produce films with consistent thickness. It has a unique driving system to produce a smooth coating on various types of materials. The flat vacuum chuck is built in to hold the substrate sheet in place, which is particularly useful when making thin film coatings.

Specifications:

|

Model |

TMH100-250 |

TMH150-250 |

TMH250-300 |

TMH250-350 |

TMH250-500 |

TMH250-800 |

|

Effective coating area(can be customized) |

100 x 250mm |

150 x 250mm |

250 x 300mm |

250 x 350mm |

250 x 500mm |

250 x 800mm |

|

Stroke length (adjustable) |

10 - 250 mm |

10 - 250 mm |

10 - 300 mm |

10 - 350 mm |

10 - 550 mm |

10 - 800 mm |

|

Vacuum chuck dimensions(W*L) |

100 x 365mm |

150 x 365mm |

250 x 400mm |

250 x 450mm |

250 x 650mm |

250 x 900mm |

|

Power supply |

110VAC or 220VAC |

|||||

|

Coating speed |

0 - 120 mm/sec variable; accuracy: 10mm/sec |

|||||

|

Vacuum pump |

One vacuum pump is included Pumping rate: 60 Hz:1.8 CFM, 50 L/min Extreme vacuum: 5 Pa, 375 microns |

|||||

|

Film applicator |

One standard film applicator is included Standard: Analog film applicator with fix coating width 0~3mm gap adjustable Coating accuracy: ±0.003mm |

|||||

|

Optional parts: Digital micrometer Adjustable width Different gap/coating thickness |

||||||

|

Heating function (selectable) |

Platen heating(standard)

1. Heating on the vacuum chuck/coating plate |

|||||

|

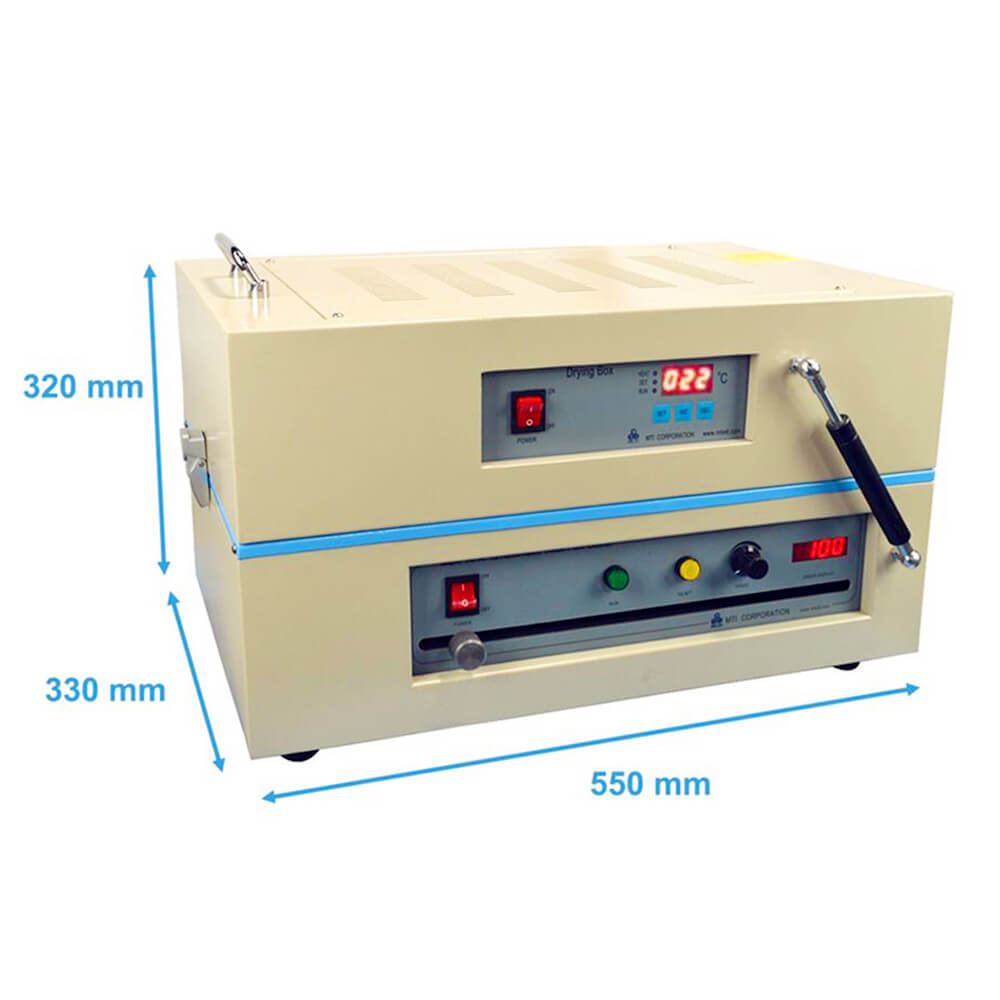

Top cover heating 1. Pre-installed on the top cover 2. Built in digital temperature controller with accuracy of +/-1°C 3. Suspension support helps open cover easily and safely 4. Max. Heating Temp: 150°C |

||||||

|

Surface finish |

▽10 |

|||||

|

Surface roughness |

Ra0.1 |

|||||

|

Vacuum board material |

5052 Aluminum alloy |

|||||

|

Compliance |

CE Certificate |

|||||

|

Warranty |

One year limited warranty with lifetime support |

|||||

![]()

Pouch Cell Process: Tube Furnace/ Muffle Furnace→ Vacuum Mixing→ Electrode Coating→ Roll press→ Electrode Cutting→ Vacuum Drying→ Cases Forming→ Top&Side Sealing→ Electrolyte Filling→ Vacuum Sealing→ Battery Analyzer

For the pouch cell assembly, we also recommend you the following items:

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975