ItemNo :

LITH-FN-10MOQ :

1Color :

optionalPort :

Xiamen PortCompliance:

CEWarranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com

Introduction

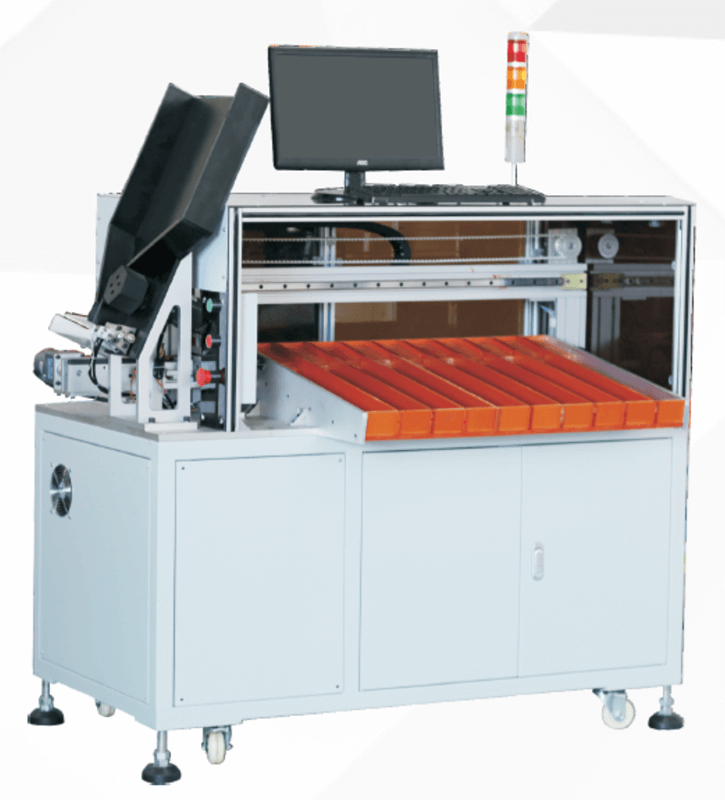

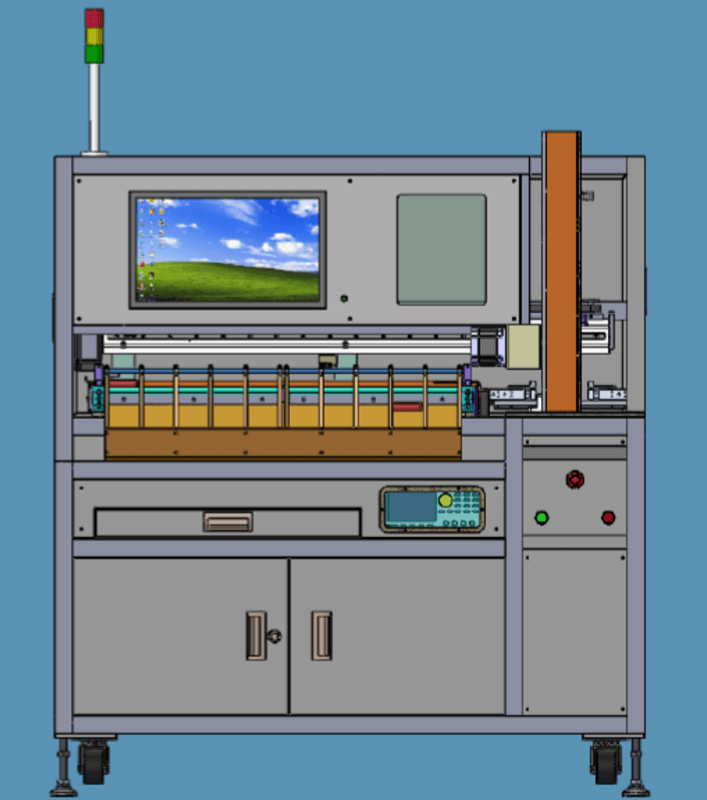

The 10-channel cylindrical battery sorter is a machine consisting of a voltage internal resistance tester, which is used to test the voltage internal resistance of batteries. The power of each battery is calculated according to the software settings of the host computer, and the batteries of different grades are converted according to the judgement results. Different channels for automatic classification of battery products.

The automatic sorting device consists of feeding mechanism, detection mechanism, automatic sorting mechanism and receiver mechanism. The machine system designs and develops the upper computer software according to the user's requirement, and automatically classifies the batteries according to the grouping information, and collects them into the corresponding receivers.

Features

1. It is a must equipment for Battery Pack Manufacturer for voltage and resistance testing and sorting.

2. 10 Channel automatic cell sorter is designed to sort cylindrical cells

3. Sort by cell's voltage and impedance up to 10 groups

4. Automatic sorting control

5. Fast sorting speed ≥90PPM

6. Easy to refill cells during the process

7. Wheels design, easy to move the machine to any operating place

Advantages

1. Stable control system

2. High configuration regulator

3. High Precision Work Procedure

4. High cost performance ratio of products

Technological Process

The battery resistance and voltage are set by the battery testing software of the upper computer, and the following functions are automatically completed by PLC:

Manual filling of batteries→wave wheel rotating feeding→belt carrying batteries→ejector cylinder jacking batteries→ test cylinder closure (test instrument uploading data, software sorting)→mechanical gripper sorting batteries.

The equipment is equipped with acoustooptic alarm, which can be sorted to complete automatic shutdown. Full material alarm, fault alarm, etc. Operating parameters can be set according to the actual requirements of customers.

Structure of Sorter

1) The equipment has compact and reasonable structure, beautiful appearance and small space occupation.

2) The equipment is simple to operate, and no professional training is required. The workers can easily master it.

3) The equipment is controlled by PLC + PC. PLC is responsible for battery feeding, transporting and collecting. PC is responsible for data acquisition of battery test instruments, voltage resistance classification, easy operation, high efficiency, labor saving and good product performance.

4) The equipment is made of high-quality thick cold-rolled sheet metal and aluminium profile frame.

5) The equipment is equipped with universal movable casters, which can move easily when shifting.

Specification:

|

Model |

LITH-FN-10 |

|

Power supply |

AC220V ± 10% 50Hz |

|

Power Consumption |

≤1000W |

|

Display Screen |

Large size LCD screen/Touch screen |

|

Compressed Air Pressure |

0.5 ~ 0.7Mpa |

|

Sorting Speed |

≥ 90PPM |

|

Chance of Damaged Product |

≤0.1% |

|

NG Equipment Failure Rate |

≤0.1% |

|

Open Circuit Voltage Accuracy |

± 0.1% rdg Display Resolution: 0.1 millivolt |

|

AC Resistance Accuracy |

± 0.5% rdg Display Resolution: 0.1 milliohm |

|

Productivity |

5000pcs/h |

|

Dimension |

1330x920x1600mm |

|

Adaptation Battery |

Cylindrical Battery (18650,32650,18500,26650,14500,21700 etc.) |

|

Receiving Channel |

10 channels |

|

Operating Temperature Range |

25 ° C ± 5 ° C |

|

Humidity |

≤85% |

|

Total weight |

300kg |

![]()

Related Machine

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975