We are pleased to announce that at the end of this month, LITH successfully shipped one cylindrical pack assembly line and 21 customized all-in-one machines. These battery pack machines have been specifically designed to meet our clients' needs, with a particular focus on educational and training purposes. Our design ensures the highest levels of safety and operability. The customized all-in-one machines are suitable for various cylindrical battery pack small-batch trial production and prototyping. They integrate processes such as battery capacity grading, sorting and matching, Battery spot welding, Battery BMS testing, comprehensive battery pack performance testing, and battery aging into one unit. Throughout the process, we worked closely with our clients to meet their specific requirements, ensuring a smooth and efficient production. Our dedicated engineers will also be on-site to assist with the installation and commissioning of the equipment. This successful collaboration once again highlights LITH's strengths in customization. We remain committed to deepening our expertise in this area to continually meet our clients' needs.

Read More

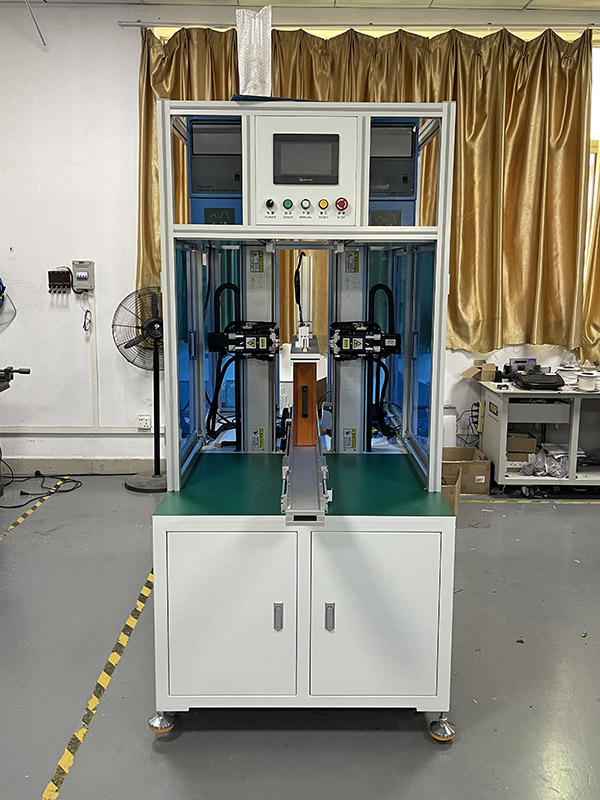

LITH Successfully Delivers Custom Large Double-Sided Spot Welding Machine for UK Client LITH is delighted to announce the successful customization and assembly of a large-scale dual-sided spot welding machine for our esteemed client in the UK. This machine boasts a stroke of 600*1200mm, making it ideally suited for the production needs of large battery packs. In addition to this customized welding machine, LITH is also excited to introduce a brand-new automatic welding machine with an upper computer. This new welding machine integrates cutting-edge control technology, enabling a higher level of automation and production efficiency, thus offering customers more options and optimized solutions. → Double-Side Automatic Welder with PC → Single-Side Automatic Welder with PC LITH is committed to continuous innovation and the enhancement of battery manufacturing technology to meet the growing global demand for high-quality battery products.

Read More

On March 15, 2024, Professor Liang from the Institute of Technology and Engineering of the Chinese Academy of Sciences purchased a pouch cell laboratory line in our company, including Hydraulic Electrode Roller Press Machine, Electrode Vacuum Planetary Mixing Machine, Electrode Doctor Blade Coater, Electrode Die Cutter, Electrode Z-Stacking Machine, Pouch Cell Forming Machine, Top & Side Heat Sealer, Electrolyte Filling Machine, Vacuum Diffusion and Degassing Chamber, Vacuum Pre-sealing Machine, Pouch Cell Final Sealing Machine, Vacuum Glove Box, etc. On June 12, 2024, LITH engineers came to the Chinese Academy of Sciences to install and debug equipment, and trained customers on the use, maintenance and maintenance of the equipment!

Read More

Prismatic Cell Production Line Project in Europe Description: Xiamen Lith Machine Limited has designed and established a prismatic cell production line for European customers. LITH provides a complete set of prismatic production technology, production line design, raw materials, and various consumables. The entire prismatic cell production line has been installed and debugged by LITH engineers at the customer's factory, and training has been provided on the use and maintenance of the equipment and all of them reach the acceptance standards. During the FAT process, the customer conducted a comprehensive inspection and evaluation of our company's product quality, production process, safety and environmental protection. After strict review and testing, the customer expressed satisfaction with our company's products and highly praised our professional ability and service attitude. The successful installation and inspection of the aluminum shell battery cell production line has not only won our company more market share, but also further enhanced our brand image and technical strength. We will continue to uphold the corporate philosophy of professionalism, innovation, and service, and provide customers with higher quality products and services. Date: March 2024 Location: Europe Customer Requirements Form: Battery Type Prismatic Cell Design capacity 100Ah,300Ah Material system LFP Main process Stacking Production capacity 2000Pcs/day Solution: (1)Design the whole line production solution of prismatic cell (2)Provide a complete set of manufacturing equipment from electrode preparation to final cell finishing process (3)Meet the customer's high capacity, high energy density, and high rate discharge requirements. Equipment List: SN. Equipment Name 1 Mixing Equipment 2 Feeding System 3 Slurry Buffer Tank 4 Auto Double Sides Slot Die Coating Machine 5 NMP Recovery System 6 Calender Machine 7 Auto Slitting Machine 8 Stamping Machine 9 Auto Stacking Machine 10 Ultrasonic Spot Welding Machine (Tab to lid welding) 11 Cover Plate Welding Machine 12 Insulator Wrapping Machine 13 Shelling &Welding Machine 14 Helium Testing Machine 15 Washing Machine 16 X-ray Tester 17 High Vacuum Oven 18 Auto Electrolyte Filling Machine 19 High Temperature Wetting 20 Negative Pressure Formation Machine 21 Laser Welding&Sealing Machine 22 OCV Tester 23 Charging Machine 24 PVC Film Pasting Machine 25 Drying Unit 26 Air Compressor Unit 27 Vacuum Unit 28 Nitrogen Generating Unit 29 Deionized Water Machine 30 Cooler 31 ACIR Tester Project Picture:

Read More

LITH Pouch Cell Lab Machines for Ningbo Oriental University of Technology On March 18, 2024, Ningbo Oriental University of Technology purchased pouch cell laboratory equipment from LITH, including Electrode Coating machine, vacuum drying box, pouch cell electrode cutter, electrode calendering machine, and pouch cell sealing machine. On April 24, 2024, LITH engineers visited Ningbo Oriental University of Technology to install and debug equipment. Our product quality and comprehensive after-sales service received unanimous praise from the customer!

Read More ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975