ItemNo :

LITH-RXG700LMOQ :

1Compliance:

CEWarranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.comX-Ray Thickness Tester Surface Density Measurement Device For Prismatic Cell Manufacturing

Ⅰ.Measurement principle and application characteristics

The measurement method is ray penetration absorption measurement, and the direct physical quantity measured is area density (gram weight). When X ray penetrates the material, the ray is reflected, scattered or absorbed by the material, resulting in some attenuation of the ray intensity, and the attenuation is positively related to the surface density of the penetrated material.

When the bulk density of the material is fixed or consistent, the thickness of the material can be measured by volume density conversion (areal density=density * thickness).

The X-ray thickness gauge is a low-energy radiation device, and the ray can be turned on and off through the power supply. Generally, no special protection is required.

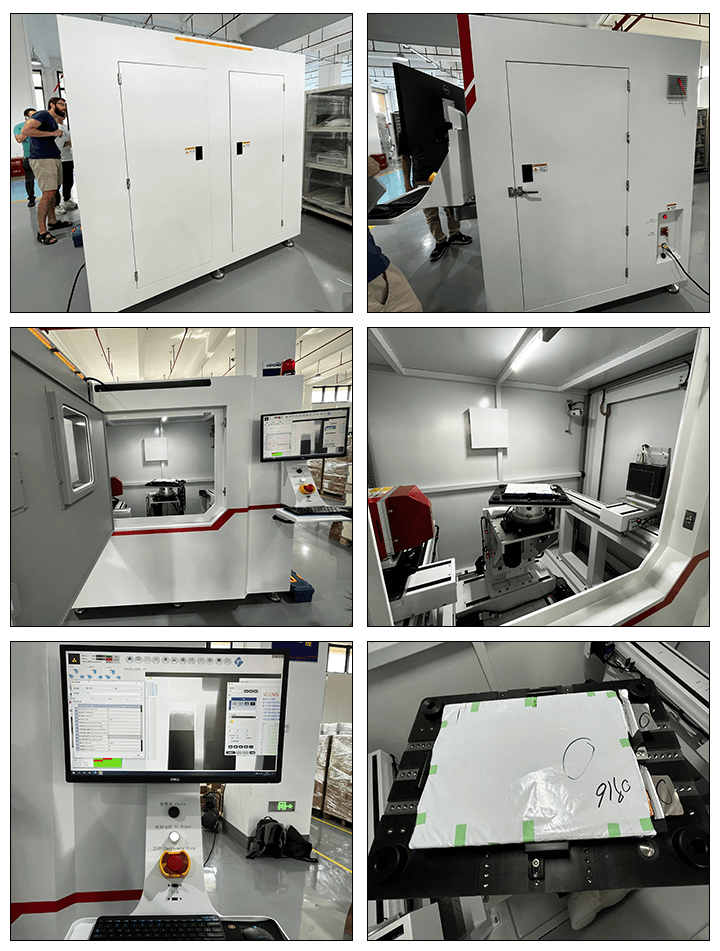

The X-ray thickness gauge generally adopts the O-type scanning frame.

The X-ray thickness gauge combines with the laser displacement sensor and uses the C-type marble scanning frame to derive the X-ray laser thickness measuring machine, which can realize the simultaneous measurement of surface density and thickness, and can be used for the measurement of surface density and head and tail thinning of lithium coating.

Ⅱ.X-ray measurement sensor with excellent performance

1)X-ray measurement sensor is the key core technology of the machine, which is built by nuclear detection experts with 20 years of experience, and has high repeatability and long-term stability rarely seen in China.

2)The X-ray transmitter adopts a double closed-loop circuit control system to ensure long-term stability of the radiation intensity and high repeatability of measurement.

3)The X-ray detector is imported from Germany's preamplifier circuit technology, which has a high signal-to-noise ratio.

4)The X-ray transmitter adopts the special slit ray collimation channel and small spot design, combined with high signal-to-noise ratio detector and software algorithm, which can provide higher spatial resolution accuracy and fringe defect recognition.

According to the actual measurement needs, the output spot of the X-ray transmitter is designed to be 5 * 5mm Φ 9mm and 2 * 12mm.

Among them, 2 * 12mm ray spot is the unique advantage technology, which can realize the size measurement of lithium coating edge thinning area.

Ⅲ.Technical features and powerful functional modules of X-ray surface densitometer/thickness gauge

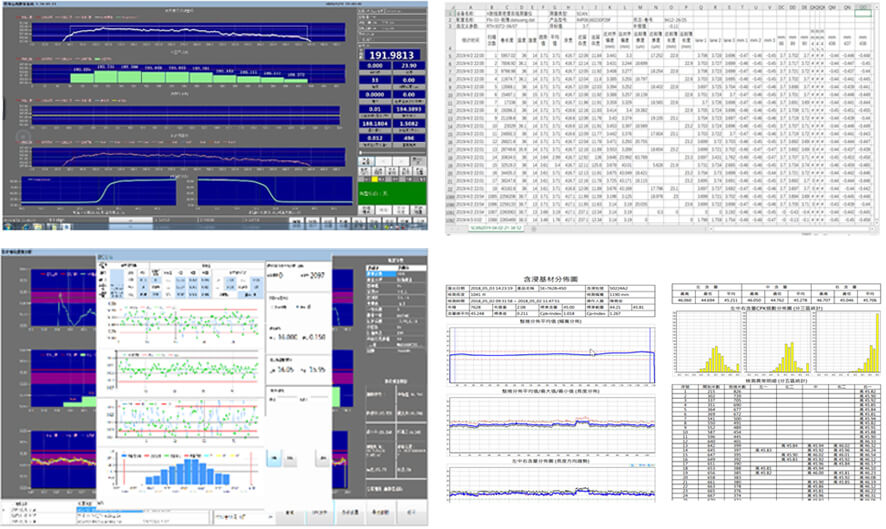

1) It can realize scanning measurement, fixed-point measurement, cyclic fixed-point measurement, and arbitrary switching between scanning and fixed-point mode.

2) Single/multiple contour lines, zoning lines, trend lines and other rich measurement curves are presented in real time, and multiple quality data are displayed.

3) The massive total value data based on database is stored in excel format, historical data is queried and traced, and historical curve is redisplayed.

4) Professional SPC statistical analysis, automatically generate quality volume reports, and can be customized according to customer needs.

5) Multiple process control solutions, real-time process monitoring, five-line quality control, multiple early warning and alarm, and over-limit marking.

6) It supports closed-loop automatic control, can dock with customer MES system, and can realize multi-rack point-to-point tracking measurement.

7) Independent research and development of data acquisition card and control board card, real-time communication system and CANOPEN bus communication transmission to ensure high-speed measurement response.

8) Better usability and friendly human-computer interface, one-button intelligent operation.

Ⅳ.Performance parameter

|

Item |

X-ray surface densitometer/thickness gauge |

X-ray&laser integrated machine |

|

Model |

RXG700L、RXG750L、RXG850L etc |

RXLG700L、RXLG750L RXLG850L etc |

|

Testing Item |

Areal density |

Area density&thickness |

|

Scanning frame |

O-scan frame |

C-scan frame |

|

Measurement method |

Scanning measurement, fixed-point measurement, cyclic fixed-point measurement |

Scanning measurement, fixed-point measurement, cyclic fixed-point measurement |

|

Measuring range |

0 ~1000 g/m² or 0~1000μm |

0 ~1000 g/m² or 0~1000μm |

|

Spot size |

Φ9mm、5*5mm or 2*12mm |

Φ9mm(ray) & 30*1200μm(laser) |

|

Sampling distance |

1mm |

1mm |

|

Repetition precision |

±0.05g/㎡ or ±0.05% |

±0.05g/㎡(ray) & ±0.4μm(laser) |

Ⅴ.Application area

On-line measurement and control of surface density (thickness) consistency of various sheets, coils or coatings such as lithium battery positive electrode coating, lithium battery diaphragm and coating, plastic film, non-woven fabric, metal foil, rubber, etc.

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975