ItemNo :

LITH-Perovskite LineMOQ :

1Port :

Xiamen PortCompliance:

CE CertifiedWarranty:

1 Year limited warranty with lifetime supportEmail :

Louis@lithmachine.comPerovskite Solar Cell Research Equipment Assembly Line

Process and equipment required

|

Process |

Equipment Name |

Model |

Website Link |

|

Solution Preparation |

Magnetic stirrer |

TMAX-SC-MS-I |

|

|

Planetary centrifugal mixer |

TMAX-ITT-300SS |

||

|

TiO2 Coating |

Vacuum Spin Coater with Plate Holder |

TMAX-4A |

|

|

DC or RF High Vacuum Magnetron Ion Sputter

|

TMAX-650MH |

||

|

Perovskite Coating

|

Bench-Top Ultrasonic Spray Pyrolysis Coating Unit with 6"×6" Heating Plate up to 500C |

TMAX-MSK-USP-02 |

|

|

Vacuum Slot Die Coating Machine

|

TMAX-MSK-AFA-PD100 |

||

|

Spiro-OMeT AD Coating |

Vacuum Spin Coater with Plate Holder |

TMAX-4A |

https://www.lithmachine.com/lab-dual-led-digital-display-high-speed-vacuum-spin-coater-instrument-with-acceleration_p1516.html |

|

Slot die coater |

TMAX-SC-SD-I |

||

|

IZO Coating

|

Liquid crystal screen magnetron sputtering instrument |

TMAX-SC-SU-I

|

|

|

Film Rolling

|

Lab Hot Roll Press Calender Machine for Rolling Coated Substrate |

TMAX-DG |

|

|

Automatic hot press with multi-segment programming function |

TMAX-RYJ-600ZG |

||

|

Substrate Cleaning |

Ultraviolet ozone cleaning machine |

TMAX-SC-UV-I

|

|

|

Plasma cleaning machine |

TMAX-SC-PE-I |

||

|

Film Drying

|

High specification vacuum dryer(Equivalent to the ossila brand in the United States) |

TMAX-SC-H-II |

|

|

Note: Substrate cleaning can be divided into pre-coating cleaning and post-coating cleaning: Uv ozone cleaning machine is used to remove impurities on the surface of the substrate, and the developer is usually used for cleaning after spin coating (this step requires the use of automatic glue dropping function and liquid leakage function).

Dryer is the customer after spinning coated the sample, put the sample into the dryer to make the film rapid molding, this can be based on customer needs, usually the solution viscosity of high film can be quickly formed without the need to use the dryer, the solution viscosity is thin difficult to form a film, you need to use the dryer. |

|||

Application field

Applications for perovskite batteries include buildings, mobile devices, wearables, transportation, outdoor and camping activities, remote areas and developing countries.

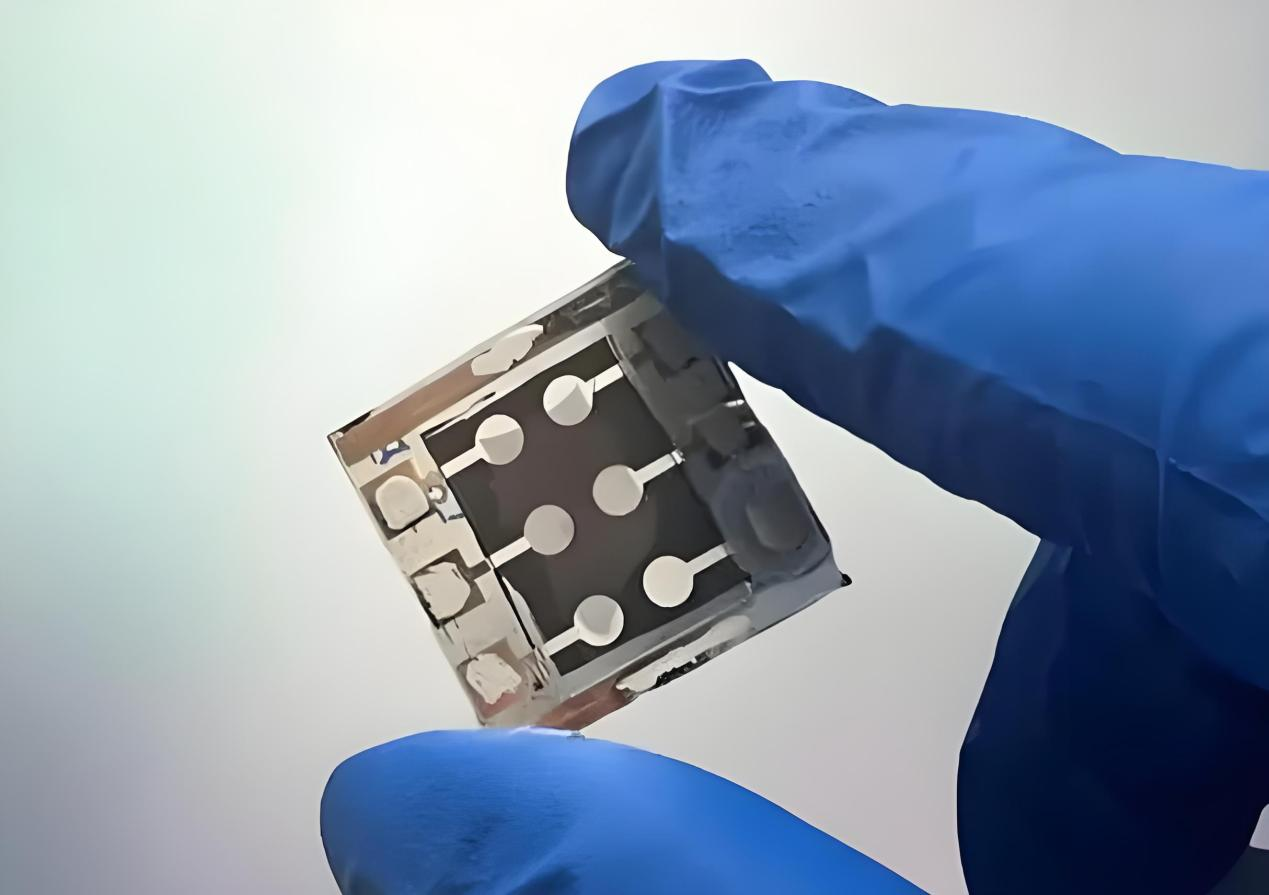

![]()

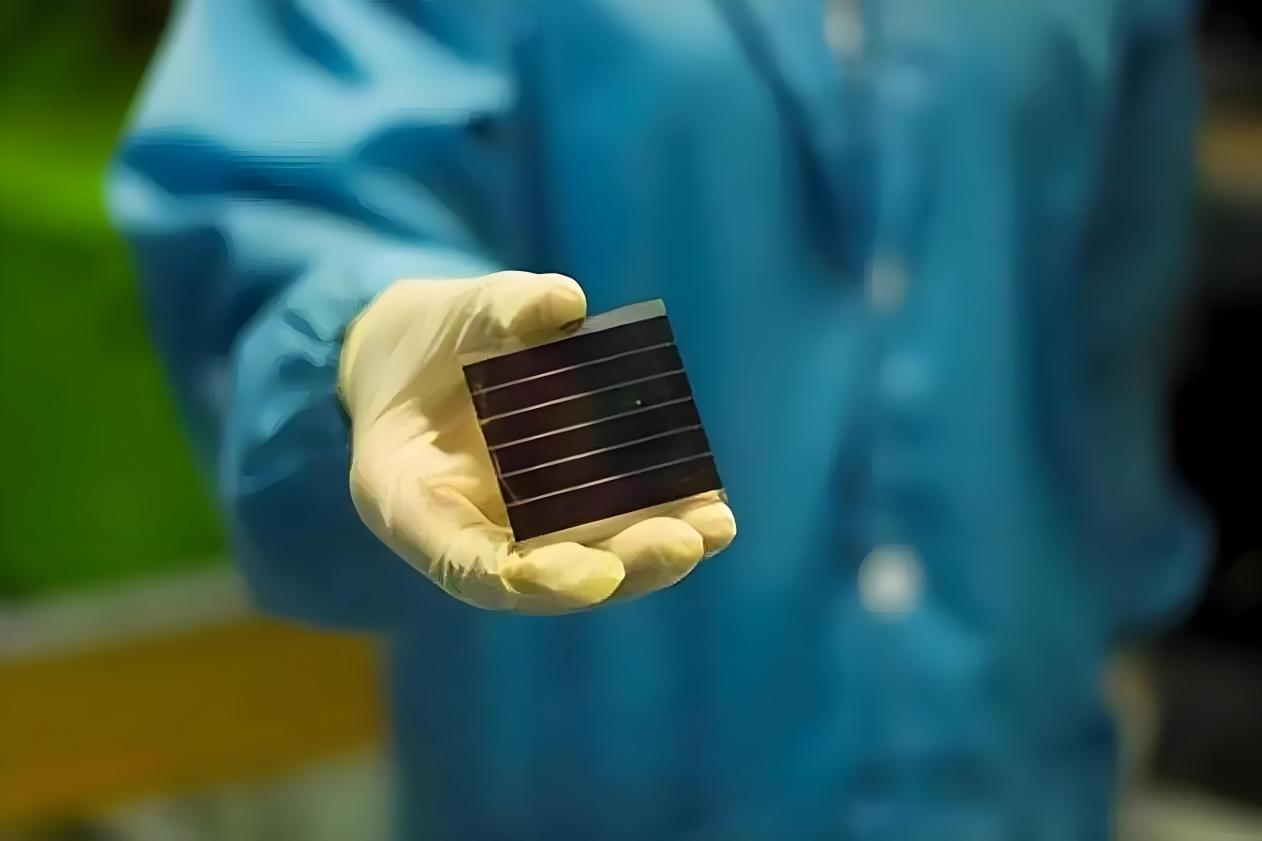

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975