ItemNo :

LITH-SWH-2MOQ :

1Delivery Time:

5 daysEmail :

Louis@lithmachine.comLab Three-Dimensional Cycloidal Oscillating Multi-Sided Operation Mixer Device

A. Use

Three-dimensional mixer formerly known as three-dimensional cycloidal mixer, also known as oscillating mixer, is currently the most advanced one of the powder, granular material mixing equipment, the machine is used in electronics (lithium cobalt oxide), ceramics, chemical, daily chemical pharmaceutical, food, light industry, electrical, machinery and various scientific research units of powder, granular material uniformity mixing.

B. Working principle

The mixing barrel of the machine can be multi-sided operation, the material has no centrifugal force, no specific gravity segregation and stratification, accumulation phenomenon, each component can have a wide weight ratio of mixing rate of more than 99.9%, and the maximum device coefficient can reach 0.9(p ordinary mixing machine is 0.4-0.6). Small footprint, for energy-saving and efficient mixing, the machine in operation due to multi-direction mixing, accelerate the flow and diffusion effect, to solve the general mixer due to centrifugal force generated by the material specific gravity segregation accumulation phenomenon, mixing without dead Angle, can effectively ensure the best quality of mixed materials.

C. Structural characteristics

The machine is composed of barrel body, frame, rotating wall, motor, decelerating device, etc., equipped with time relay to control the time, the rotating wall is made of high-quality stainless steel 304, the barrel body is polished, the replacement barrel body is less than 130mm in diameter/less than 190 in height, the flow effect is good when the material is mixed, no dead Angle, no pollution of the material, easy to operate. Easy to clean, smooth appearance, beautiful and generous.

D. Main technical parameters

|

Barrel body |

φ130mmX190mm height |

|

Reference overall dimension |

500x600x420mm(subject to actual objects) |

|

Weight |

60KG |

|

Power source |

Single-phase 220V,50HZ |

|

Protection |

Open cover stop protection, overload and overcurrent protection |

|

Motor specification |

150W |

|

Speed regulation |

Infinite digital display speed regulation |

|

Spindle speed |

0-87r/min |

|

Volume |

2L |

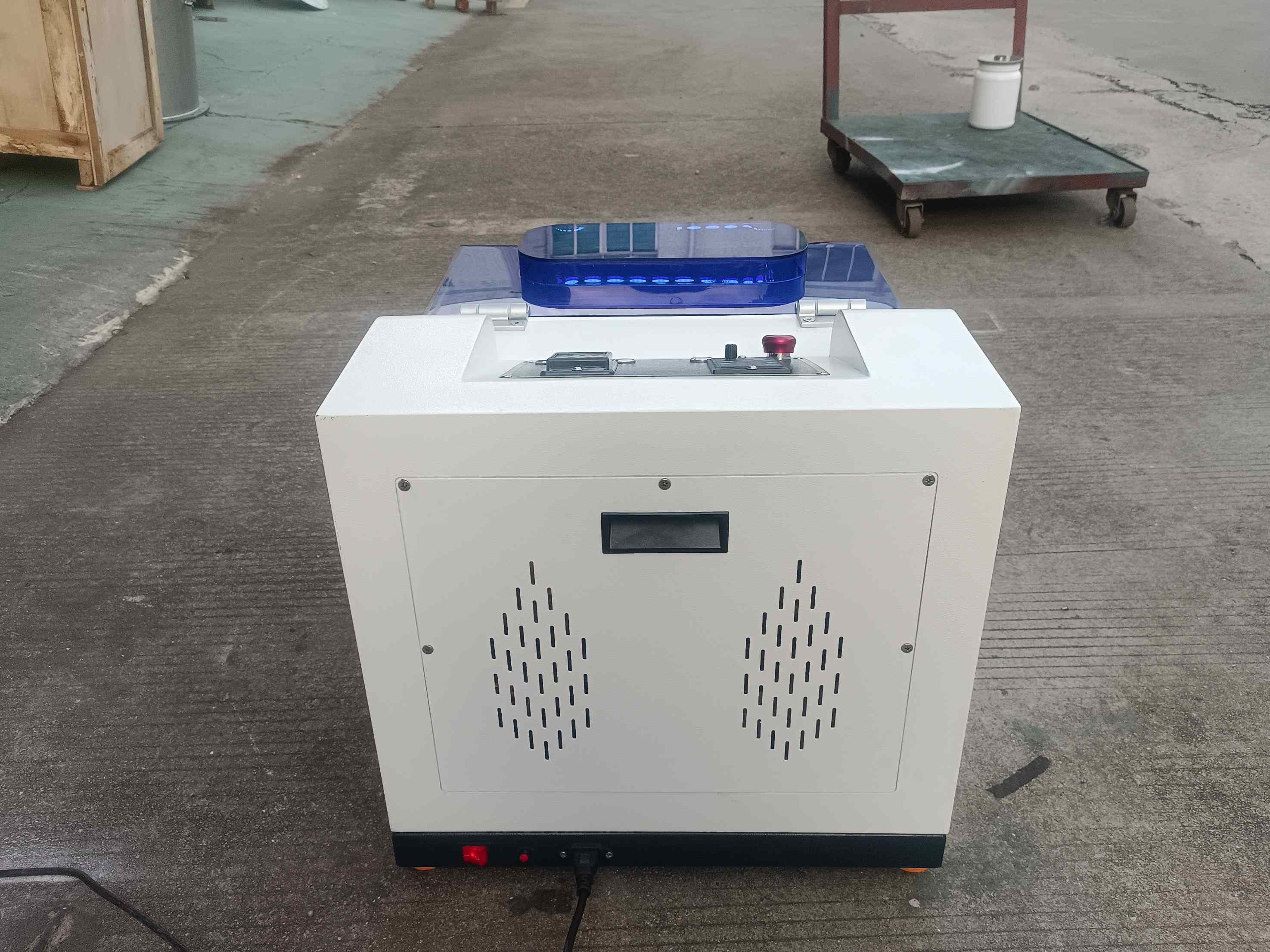

E. Related reference pictures

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975