ItemNo :

LITH-BSW07MOQ :

1Warranty:

2yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com

Introduction

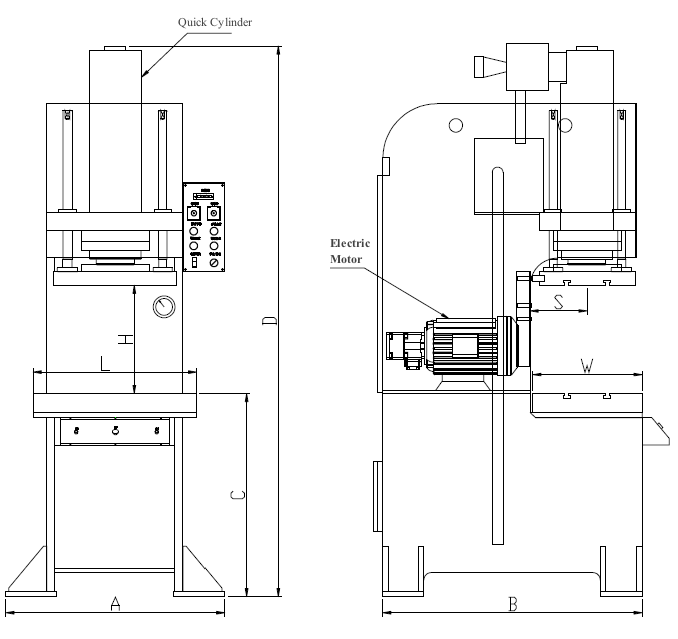

The single-column hydraulic machine body is a C-type floor-standing structure, open on three sides, easy to operate, and tempered after welding to ensure that the frame will never deform. It is mainly used for press fitting, assembly, shallow drawing of metal products, and forming pressing. , embossing, is a general-purpose equipment for motors, shafts, auto parts, electronic hardware products, internal combustion engines, textile machinery, washing machines, electrical appliances and other factories.

Product parameters

|

Model |

BSW07 -10T |

BSW07 -20T |

BSW07 -30T |

BSW07 -40T |

BSW07 -50T |

BSW07 -60T |

|

|

Nominal pressure(T) |

10 |

20 |

30 |

40 |

50 |

60 |

|

|

Maximum working pressure |

21 |

21 |

21 |

21 |

21 |

21 |

|

|

Surface height (E) mm |

850 |

850 |

850 |

850 |

850 |

850 |

|

|

Maximum opening |

400 |

400 |

500 |

550 |

550 |

600 |

|

|

Deep throat (s) mm |

200 |

200 |

225 |

225 |

250 |

250 |

|

|

Maximum stroke(mm) |

300 |

300 |

300 |

300 |

300 |

400 |

|

|

Work bench size

|

Left and right (L) mm |

500 |

500 |

550 |

550 |

650 |

650 |

|

Before and after (W) mm |

400 |

400 |

450 |

450 |

500 |

500 |

|

|

Speed |

Rated load speed (mm/s) |

165 |

165 |

165 |

165 |

155 |

155 |

|

Working speed(mm/s) |

24 |

24 |

24 |

18 |

15 |

15 |

|

|

Return speed(mm/s) |

140 |

140 |

140 |

125 |

125 |

125 |

|

|

Main frame size(mm) |

700x950 x2050 |

700x950 x2060 |

760x950 x2100 |

780x950 x2150 |

800x950 x2150 |

830x1000 x2350 |

|

|

Power(Kw) |

2.2Kw |

3.7 Kw |

3.7Kw |

3.7 Kw |

5.5 Kw |

5.5 Kw |

|

Features

1. Floor-standing hydraulic press has the characteristics of good rigidity, stability and high speed because it is a welding mechanism as a whole.

2. This series of hydraulic presses uses 2-20MPA liquid pressure as the power source, and external three-phase AC380V 50HZ or three-phase AC220 60HZ AC power supply.

3. This series of equipment uses liquid as the medium to transfer energy. It adopts advanced sub-cylinder hydraulic circuit, the oil temperature is low, the idle speed is above 150MM/sec, and the working speed is below 30 MM/sec.

4. The equipment is on standby, and the noise does not exceed 75 decibels when moving up and down.

5. It can be divided into manual and semi-automatic control modes. Manually, the press-fit upper mold can be stopped in any stroke range. It can be equipped with an emergency rebound button or an infrared hand guard device.

6. The press-fit stroke of this series of presses is generally controlled by a timer, pressure switch, position sensor, or the customer's own mold.

7. The height of the press-fit spindle can be adjusted by the timer or the position sensor within any stroke range.

8. Pressure, stroke, holding time, closing height can be adjusted by the customer for easy operation; with automatic counting function, can also be equipped with force measuring display, intelligent temperature controller, can be customized according to customer requirements.

9. The hydraulic mechanical output range of this series is available in various specifications of 15tf-100 tf. (1tf=1000kgf=9.8KN).

Dimension

Application

Pictures

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975