ItemNo :

LITH-QP200MOQ :

1Warranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.comEdge Trimming Machine For Pouch Battery Research

LITH-QP200 is widely used in the final steps of pouch cell battery pilot-scale production line to ensure a smooth, neat and tidy casing edge.

SPECIFICATIONS:

|

Max. Power Consumption |

20W |

|

Working Voltage |

110 - 240VAC, single phase |

|

Compress Air Pressure Requirement |

0.5 - 0.7 MPa (Each stroke will consume 0.09L air ) |

|

Size Info (Trimming Width/Length) |

|

|

Stroke Frequency |

~10 seconds per trial |

|

How to use this Tool Suite |

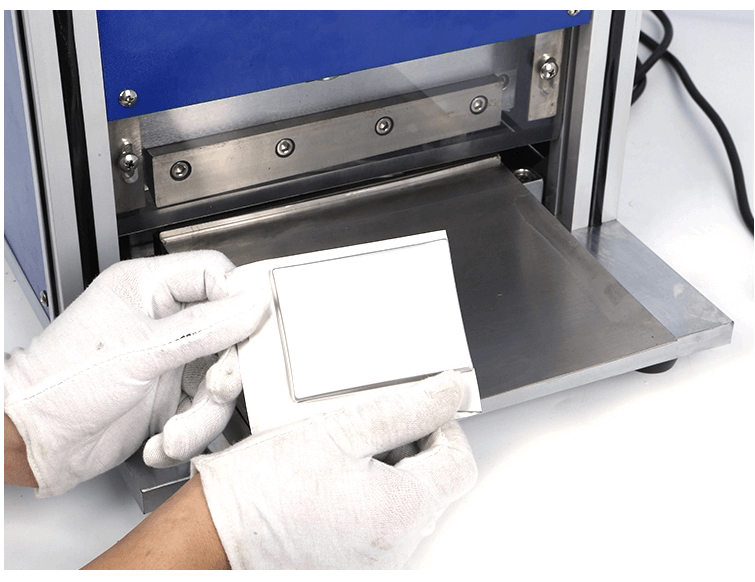

When the pouch cell is fabricated, an uneven edging excess is expected. In order to make a neat and tidy cell with smooth edge just like the commercial pouch batteries, please follow the steps in below: |

|

Net Weight |

35kg |

|

Product Dimensions |

L320x W180x H340mm |

|

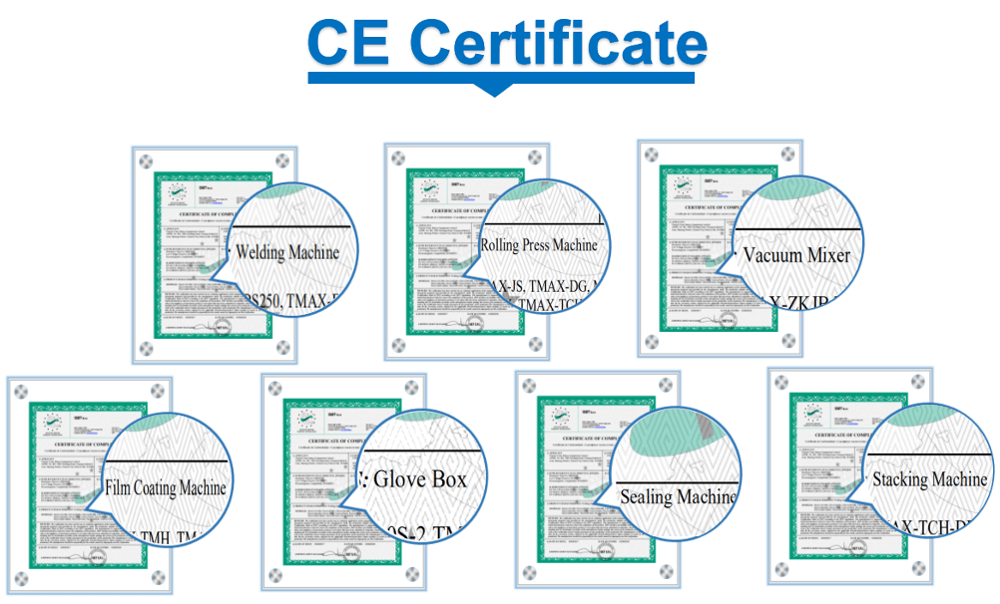

Compliance |

CE Certificate |

|

Warranty |

One Year limited warranty with lifetime support |

![]()

Pouch Cell Process: Tube Furnace/ Muffle Furnace→ Vacuum Mixing→ Electrode Coating→ Roll press→ Electrode Cutting→ Vacuum Drying→ Cases Forming→ Top&Side Sealing→ Electrolyte Filling→ Vacuum Sealing→ Battery Analyzer

For the pouch cell assembly, we also recommend you the following items:

|

|

|

|

|

|

|

|

|

|

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975