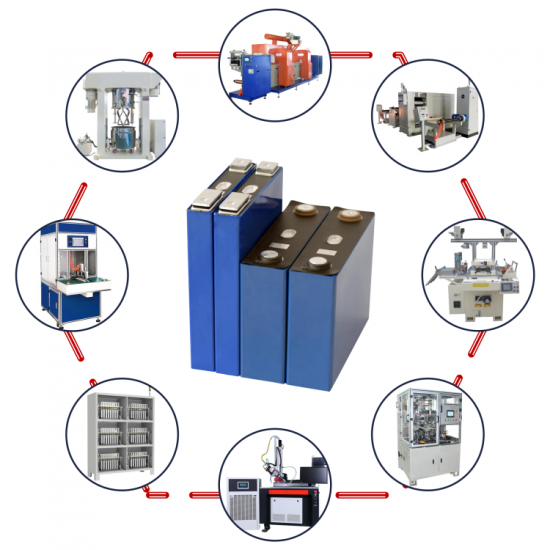

Prismatic battery manufacturing machine requires specialized equipment to assemble the battery cells efficiently and ensure high-quality production. The specific equipment used in prismatic battery manufacturing can vary depending on the manufacturer and the scale of production. However, here are some common types of equipment used in prismatic battery manufacturing:

Coating Machine:

Purpose: Applies a thin layer of electrode slurry onto the current collector.

Details: This machine is essential for coating electrodes with the active material, conductive additives, and binders.

Roll Press Machine:

Purpose: Compacts the coated electrodes to the desired thickness.

Details: Prismatic cell production machine ensures uniform thickness and density of the electrode layers.

Cutting Machine:

Purpose: Cuts the coated electrode sheets into specific sizes.

Details: Precision is crucial to meet the design specifications of the prismatic battery cells.

Stacking Machine:

Purpose: Stacks the coated electrodes and separators in a precise order to form the battery cell.

Details: This machine is crucial for the accurate assembly of the prismatic battery cell.

Winding Machine:

Purpose: Winds the electrode stack into a jelly roll before placing it into the prismatic cell casing.

Details: Commonly used in cylindrical cell manufacturing, the winding process might be adapted for certain prismatic cell designs.

Injection Molding Machine:

Purpose: Encases the wound electrode stack in a prismatic-shaped housing.

Details: Injection molding ensures the proper shape and structure of the prismatic battery cell.

Formation and Aging Chambers:

Purpose: Subject the assembled cells to charging and discharging cycles to stabilize performance.

Details: Formation chambers are critical for activating the electrochemical processes within the prismatic battery cells.

Spot Welding Machine:

Purpose: Welds the tabs onto the electrodes to create electrical connections.

Details: Ensures a reliable connection for efficient electron flow within the prismatic cell.

Laser Welding Machine:

Purpose: Welds external leads to the tabs of the prismatic cell.

Details: Utilizes laser technology for precise and efficient welding.

Testing and Quality Control Equipment:

Purpose: Performs various tests to ensure the quality and performance of prismatic battery cells.

Details: Includes Prismatic cell manufacturing equipment for voltage testing, capacity testing, and other quality control measures.

Packaging Equipment:

Purpose: Packages the individual prismatic cells into larger battery packs.

Details: This equipment ensures proper insulation, protection, and arrangement of cells within the pack.

Automation and Robotics:

Purpose: Integrates automation and robotics for efficient and precise handling of materials and components.

Details: Improves production speed, accuracy, and reduces manual labor.

These are general categories of equipment used in prismatic battery manufacturing, and specific equipment models may vary based on the manufacturer's design and production requirements.

No. 5 Nanshan Road, Huli District, Xiamen City, Fujian Province, China

Subscribe to us

Subscribe to us ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975