A Pouch Cell pilot equipment is a type of equipment used to produce and test prototype pouch cells for lithium-ion batteries. It typically consists of several components, including:

1) Electrode preparation equipment: This includes machines for slitting, winding, and coating the electrode materials. The coating process may use a doctor blade or a slot die to apply a thin layer of the electrode material onto the current collector.

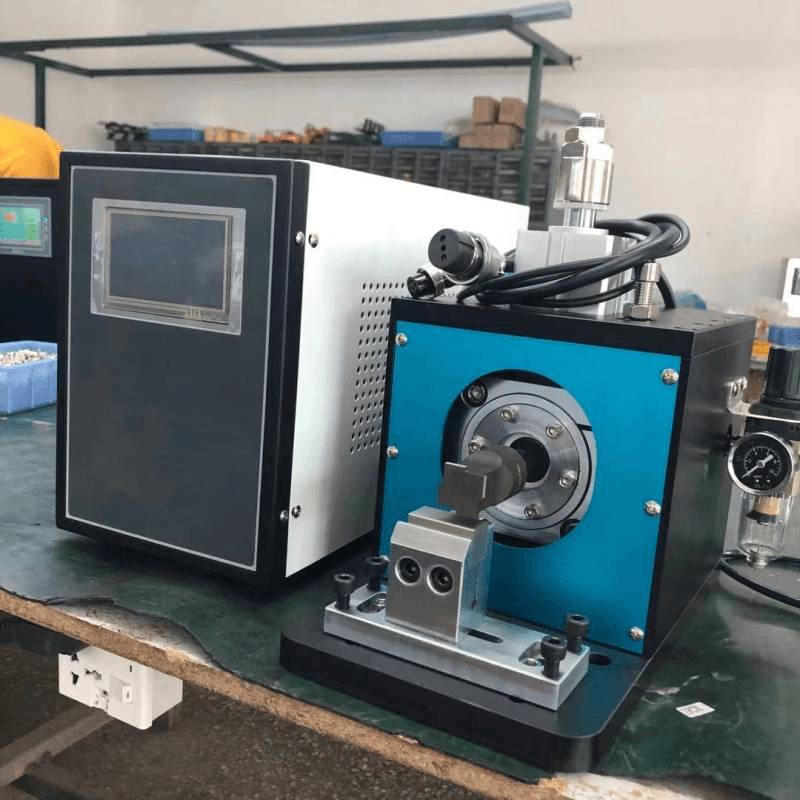

2) Pouch cell assembly equipment: This includes machines for assembling the positive and negative electrodes with the separator to form a pouch cell. The assembly process may use a continuous or intermittent sealing method, such as heat sealing or ultrasonic sealing.

3) Electrolyte filling equipment: This includes machines for filling the pouch cell with electrolyte, which is a critical component of the battery cell chemistry.

4) Pouch Cell Formation equipment: This includes machines for charging and discharging the pouch cell to activate the electrochemical reaction and stabilize the cell's performance.

Testing and quality control equipment: This includes machines for testing the performance of the pouch cell, including its capacity, cycle life, and safety features.

Pouch Cell pilot line offer several advantages over other types of lithium-ion battery production equipment. They allow for greater flexibility in cell design, as pouch cells can be made in a wider range of sizes and shapes compared to cylindrical or prismatic cells. Additionally, they are often more cost-effective for producing small quantities of cells for research and development purposes.

Pouch Cell pilot machines are essential tools for the efficient prototyping and testing of lithium-ion battery cells. They help accelerate the development process and improve the quality and performance of battery cells, enabling the production of more reliable and efficient energy storage solutions.

No. 5 Nanshan Road, Huli District, Xiamen City, Fujian Province, China

Subscribe to us

Subscribe to us ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975