ItemNo :

LITH-DJR300MOQ :

1Warranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com

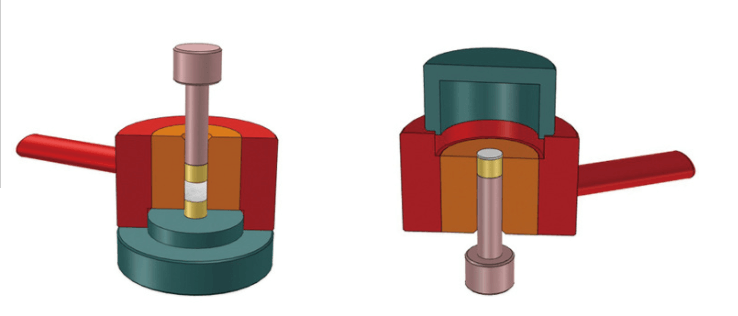

300℃ Cylindrical Heatable Mould for Pellet Formation

Heating mold is developed on the basis of common mold, which can heat and pressurize the mold samples through intelligent temperature controller. This kind of mould can be used to press powder or particle samples into cylindrical sheet or cylinder shape, and the specific mould size and shape can be customized according to customer requirements. It is suitable for rubber, plastic, leather, chemical industry, pigment, electronic appliances, textile, hardware and other fields. It is a complete set of equipment for engineering and technical personnel of colleges and universities and research institutes to carry out spectrum detection and qualitative analysis.

Standard configuration

Electric heating mold(customizable) 1 set

High temperature insulation board 1 set

Temperature controller 1 set

Optional

Hydraulic press machine

Water cooler→It is recommended to configure water-cooled machine if rapid cooling is required after mold heating.

Technical specifications

|

Drawing of forming sample |

|

|

Shape of compressible sample |

Cylinder etc. other shapes can be customized |

|

Mold heating temperature |

RT-300℃(the mold heating temperature can be up to 500℃ at extra fees) |

|

Thermostat type |

PLC program digital temperature controller, RT - 600℃, accuracy 0.1℃ |

|

Power supply |

220V/300W |

|

Common mold specifications |

Ф6、Ф8、Ф10、Ф12、Ф13、Ф15、Ф18、Ф20、Ф25、Ф30... The mold size can be customized |

|

Mould material |

Alloy tool steel: Cr12MoV (hard alloy steel is available at extra fees) |

|

Mould hardness |

HRC60-HRC62 |

|

Mold cavity depth |

45mm |

|

Mold dimensions |

Ф78×138mm |

|

Mold weight |

2.7kg |

|

Standard configuration |

Electric heating mould 1 set + heat shield 1 set + intelligent temperature controller 1 set (hydraulic press and water cooler are optional) |

|

Calculation formula of die pressure |

Area of oil cylinder / area of mould × pressure gauge reading = actual pressure of die. Do not overpressure! |

|

Note |

The above indicators are for reference only, we can customize various specifications, materials, shapes of molds according to customer needs |

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975