ItemNo :

LITH-408-DMOQ :

1Warranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com150C Humidity Alternating Temperature Test Chamber for Battery Testing

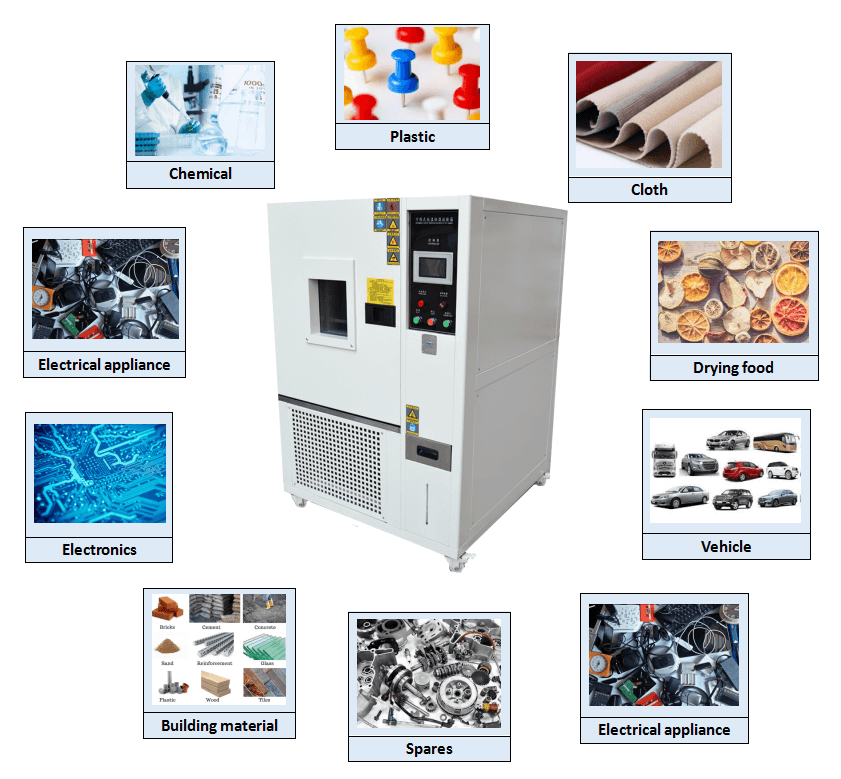

The temperature and humidity test chamber can accurately simulate the complex natural environment of low temperature, high temperature, high humidity, low temperature and low humidity, which is suitable for the product detection of plastics, electronics, food, clothing, vehicles, metals, chemicals, building materials and other industries.

Technical parameter

|

Model |

TMAX-50L |

TMAX-80L |

TMAX-225L |

TMAX-408L |

TMAX-800L |

TMAX-1000L |

|

|

Inner chamber size (CM) |

35*45*35 |

50*40*40 |

50*60*75 |

80*60*85 |

80*100*100 |

100*100*100 |

|

|

Power (- 40 ℃) |

4.5(KW) |

5.0(KW) |

6.0(KW) |

7.0(KW) |

8.5(KW) |

9.5(KW) |

|

|

Performance

|

Temperature range |

A:-20℃~150℃ B:-40℃~150℃ C:-60℃~150℃ D:-70℃~150℃ E:-70℃~180℃ Customized temperature is available |

|||||

|

Humidity range |

20~98%R.H Customized humidity is available |

||||||

|

Fluctuation / uniformity |

±1.5℃/±2℃ |

||||||

|

Humidity deviation |

±3%R.H |

||||||

|

Heating rate |

About 1.0~3.0℃/min |

||||||

|

Cooling rate |

About 0.5~1.0℃/min |

||||||

|

Control system

|

Controller |

"Temi" brand programming temperature instrument, HD real color LCD touch screen |

|||||

|

Accuracy range |

Setting accuracy: temperature 0.1 ℃, humidity 1% R.H, Indication accuracy: temperature 0.1 ℃, humidity 1% R.H |

||||||

|

Temperature and humidity sensor |

Platinum resistor PT100Ω/MV |

||||||

|

Heating system |

Fully independent system, Ni Cr alloy electric heating heater |

||||||

|

Humidification system |

External isolation type, all stainless steel shallow surface evaporation humidifier |

||||||

|

Dehumidification system |

Adopt the dew point temperature laminar contact dehumidification method of evaporator coil |

||||||

|

Water supply system |

Humidification water supply adopts automatic control, and can recover residual water, save water and reduce consumption |

||||||

|

Refrigeration system |

French "Tecumseh" totally enclosed air-cooled single-stage or cascade compressor refrigeration mode |

||||||

|

Circulation system |

Motors with low noise and temperature resistance - multi blade centrifugal fans |

||||||

|

Materials

|

Outer box material |

High quality carbon steel plates. Phosphorized electrostatic spray or SUS304 stainless steel |

|||||

|

Inner box material |

Stainless steel high quality mirror plate |

||||||

|

Thermal insulation material |

Polyurethane rigid foam / superfine glass fiber wool |

||||||

|

Door frame insulation |

Double layer high and low temperature aging resistant silicone rubber door sealing strip |

||||||

|

Standard configuration |

Multi layer heating defrosting with lighting glass window 1 set, test sample rack 2, test lead hole 1 |

||||||

|

Safeguard |

Leakage, short circuit, overtemperature, water shortage, motor overheating, compressor overpressure, overload, overcurrent protection |

||||||

|

Supply voltage |

AC220Vor 380V±10% 50±0.5Hz |

||||||

|

Operating ambient temperature |

5℃~+30℃ ≤85%R.H |

||||||

![]()

Pouch Cell Process: Tube Furnace/ Muffle Furnace→ Vacuum Mixing→ Electrode Coating→ Roll press→ Electrode Cutting→ Vacuum Drying→ Cases Forming→ Top&Side Sealing→ Electrolyte Filling→ Vacuum Sealing→ Battery Analyzer

For the pouch cell assembly, we also recommend you the following items:

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975